- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2017

- Industrial research

- Knowledge and technology transfer

Knowledge and technology transfer

Scintillators: the key to a successful endeavour

Scintillators are a must-have in synchrotron sources. Utilising in-house expertise, the ESRF started producing these advanced components eight years ago and, in 2017, we achieved record sales with almost 200 scintillators sold since the start of production and an ever-increasing demand.

Beamlines on synchrotrons worldwide need many specific components in order to carry out specialised and state-of-the-art experiments. Scintillators are essential components that make X-rays visible so they can be detected with cameras.

The sub-micrometre resolution and high image contrast demanded by today’s experiments require scintillator films with thicknesses in the range of 1-20 μm that also provide high optical quality and uniformity. Thin scintillators minimise degradations due to focusing defects, diffraction and spherical aberrations, therefore boosting the image contrast and spatial resolution. However, the sophisticated techniques required to grow such crystals and their high specificity means that very thin single crystal film scintillators are not commercially available.

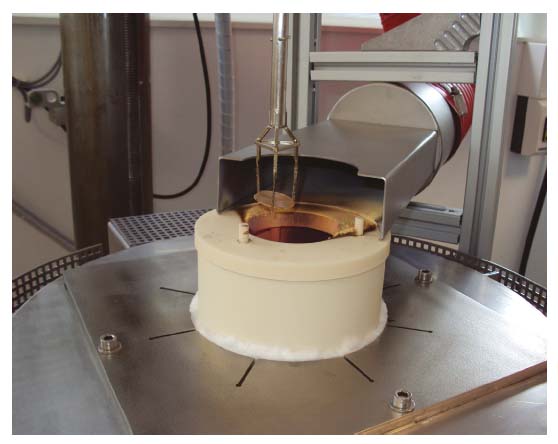

In April 2010, the ESRF established a unique liquid phase epitaxy facility for single crystal film scintillators (Figure 144). Liquid phase epitaxy is a technique whereby scintillating crystal layers are grown on a solid single crystal substrate immersed in a melt. Its key appeal for synchrotrons is that it produces a homogeneous distribution of dopant activator ions within the film (the host material absorbs X-rays and the dopants emit light). Moreover, the epitaxial growth on a high-density substrate provides radiation protection for the optics of the X-ray detector system, as well as a rigid support for easy handling and cleaning.

|

|

Fig. 144: A single crystal film scintillator, after growth and melt characterisation, fixed on its platinum holder. |

Licensing RF cavity combiners

Our licensing activities have continued throughout 2017. One of the most outstanding examples is the agreement for a radio frequency (RF) cavity combiner with SigmaPhi.

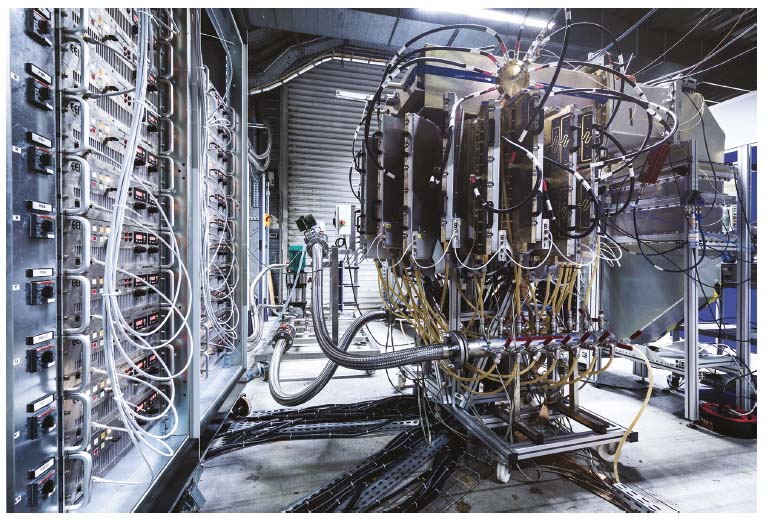

SigmaPhi is a French company that designs, makes and measures magnetic systems and beam transport lines for particle accelerators. With this licence agreement, the highly experienced ESRF RF group has transferred expertise and design support for RF cavity combiners for solid-state amplifiers to SigmaPhi Electronics (formerly part of Bruker). In order to combine the power of hundreds of transistor amplifier modules for the generation of radio frequency power at the 100 kW level, complicated coaxial power combiner trees are generally used. With funding from the EU, in the frame of the FP7/ESFRI/CRISP project, Michel Langlois, from the ESRF RF Group, developed a cavity combiner that combines the power from the solid-state amplifier modules in one stage, by means of coupling loops all around the cylindrical cavity wall (Figure 145). It results in a much more compact and cost-effective device that minimises the combiner losses. An 85 kW prototype was successfully tested at the ESRF two years ago.

|

|

Fig. 145: The in-house-developed RF cavity combiner is licensed to SigmaPhi Electronics and could eventually become the basis for a replacement of obsolete klystron transmitters. |