- Home

- Industry

- Applications and case studies

- Metallurgy

Metallurgy

The high-energy beams of the ESRF are used extensively in the domain of metallurgy because of their high penetration depth within metallic samples. The beamlines can accommodate model furnaces and processing devices permitting operando data collection. Operando experiments can involve high frame rates, for example, frame rates reaching 50,000 frames per second have been used in radiography. Diffraction and imaging techniques, often used together, are the most commonly selected but they can also be combined with other techniques such as fluorescence mapping for chemical sensitivity.

Areas of research include:

- Solidification of alloys

- Welding

- Additive manufacture

- Residual strain mapping of engineered components

- Study of materials under stress and conduction of fatigue tests

- 3D mapping of grains, including orientation and strain

- Phase transformations

- Sintering

- Elemental analysis and chemical mapping

Complementary techniques are available at the ILL neutron source nearby, which provides neutron techniques that are highly complementary to X-ray techninques for metallurgy.

For other relevant case studies, please consult the pages Aerospace and Automotive and Engineering.

CASE STUDIES

Company or institute

School of Metallurgy and Materials, University of Birmingham; School of Computing and Mathematical Science, University of Greenwich; Mechanical Engineering, University College London.

Challenge

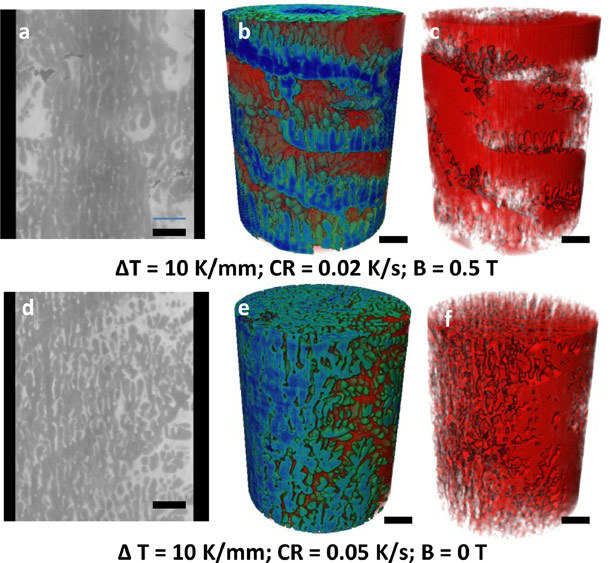

A magnetic field can be used to control the microstructural evolution of solidifying metals and alloys. In particular, the interaction of liquid metals with the imposed magnetic field can drive or disrupt inter-dendritic flow, a phenomenon known as magneto-hydrodynamics, and alter microstructural evolution. The aim of the research at the ESRF was to use high-speed X-ray tomography to follow the microstructural evolution in an alloy solidifying within a magnetic field.

Sample

The sample was an alloy of Al-15Cu (weight percent). A proprietary furnace inside a magnetic field was used in the experiment.

Solution

In an in situ experiment at beamline ID19, the molten alloy was cooled at a rate of 0.02 k/s, while being rotated at 0.5 Hz within a magnetic field of 0.5 T. Tomgrams captured over 1 second every 16 seconds recorded the formation of an Archimedes’ screw-like structure.

Benefits

The tomographic images captured extensive details of solidification of the alloy including the growth of α-Al dendrites and even their remelting into the Cu-Al eutectic under the circulatory effect on the eutectic of the magnetic field. The researchers were able to reveal the evolution, dynamics and mechanisms of solidification within a magnetic field by combining these results with high-performance computational simulation. They discovered a new mechanism for the formation of the screw structure under fast rotation. Applications of this research could include macro segregation in materials refinement and recycling, and improving mechanical properties in cast structures.

Reference

Revealing the mechanisms by which magneto-hydrodynamics disrupts solidification microstructures, B. Cai, A. Kao, E. Boller, O.V. Magdysyuk, R.C. Atwood, N.T. Vo, K. Pericleous, P.D. Lee, Acta Materialia 196, 200-209 (2020); DOI: 10.1016/j.actamat.2020.06.041.

Company or institute

German Aerospace Center (DLR)

Challenge

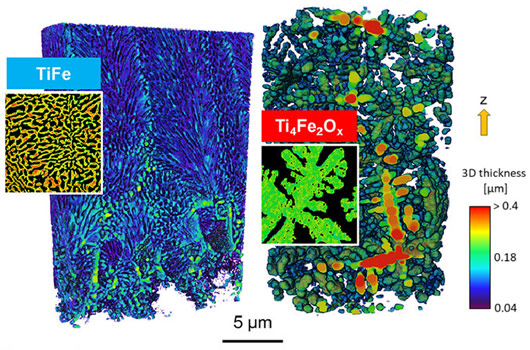

While eutectic titanium-iron-based alloys with fine microstructures have been around for several years, the production of these alloys has been restricted to laboratory investigations because of a lack of suitable processing methods for large components. Laser-based additive manufacturing provides the opportunity to fabricate parts with sizes of industrial relevance, while also providing a means to achieve rapid solidification. Therefore, it was the method chosen to produce a high-strength titanium-iron-based alloy with extremely fine microstructure. The challenge at the ESRF was to characterise this novel material with sufficient resolution to visualise the sub-micrometre detail of the alloy’s constituent phases in 3D.

Sample

Powders of Ti and Fe were blended to obtain a Ti-rich eutectic composition. Samples of the fused material were produced in a commercially available selective laser melting system.

Solution

The alloy samples were scanned using near-field synchrotron ptychographic X-ray computed tomography (NF-PXCT) at beamline ID16A with actual spatial resolution around 40 nm. 3D reconstructions of the samples were built and their segmentation was used to permit visualisation and quantification of the various phases within the alloy.

Benefits

The hierarchical ultrafine microstructure of the alloy was revealed in 3D and quantified using NF-PXCT. Thus, NF-PXCT provided unique quantitative information about the internal ultrafine architecture of the alloy, for which inter-lamellar spacings down to ~ 30–50 nm were achieved, revealing the potential of laser-based additive manufacturing to generate microstructures smaller than those obtained by classical rapid solidification techniques for bulk materials.

Reference

Ultrafine eutectic Ti-Fe-based alloys processed by additive manufacturing – A new candidate for high temperature applications, J. Gussone, K. Bugelnig, P. Barriobero-Vila, J. Cesar da Silva, U. Hecht, C. Dresbach, F. Sket, P. Cloetens, A. Stark, N. Schell, J. Haubrich, G. Requena, Applied Materials Today 20, 100767 (2020); doi: 10.1016/j.apmt.2020.100767.

Company

TU Delft together with steel manufacturers

Challenge

The twin towers collapsed in 2001 because the steel that kept them standing couldn´t resist the fire. The changes in temperature modified the microstructure of the steel and it lost its strength, making the towers crumble. Knowing what happens inside steel (the nucleation process) when it is submitted to high temperatures could help find a better composition for this alloy.

Sample

Steel.

Solution

3D X-ray diffraction at beamline ID11 has proven a unique technique to track the nucleation process inside steel as it is submitted to temperatures of 1000 C. Scientists came up with a furnace that could be compatible with the beamline and that had temperature control. They found that nucleation, which is a key process in metals, happens quicker than literature had predicted: there are special places, like grain corners or edges in the material where nucleation takes place more easily than other areas. Amongst these corners and edges there are ones that are preferred for nucleation. Controlling the nucleation means controlling the properties of the material.

Also, the crystals in the steel become coarser at higher temperatures, which decreases the material's strength. Scientists are currently testing the replacement of potentially scarce elements in the alloying process of steel by other elements more widely available.

Benefits

A better “recipe” for steel using less alloying elements would make the material more fire-resistant, less expensive and easier to recycle whilst maintaining its properties.

Sharma H., et al., Scientific Reports 6, 30860 (2016); DOI: 10.1038/srep30860