- Home

- Industry

- Applications and case studies

- Polymers

Polymers

Synthetic polymers can be found in food additives, composite materials, drug packaging, artificial organs and solar cells. Biopolymers, such as DNA, actin, collagen and fibrin, play important roles in the body. Aside from the widely used, technical polymers have been designed or processed with particular properties in mind, irrespective of their chemical composition. Functional polymers, on the other hand, are usually selected based on specific chemical groups rather than physical properties. These tend to be exploited for novel optical and electronic applications, such as gas sensors.

At the ESRF, polymers have been one of the main subjects of research since its early days. Thanks to the ESRF, researchers can now:

- Carry out time-resolved studies to monitor molecular chains and hydrogen bonds in polymers.

- Use of microfocus X-ray beams to characterise nanostructure of fibre-reinforced composites and high performance fibres.

- On axis scanning microdiffraction for skin-core morphologies.

- Measurements of the strains in metal and ceramic phases separately and simultaneously in metal matrix composites using X-ray diffraction.

- Following the internal failure mechanisms of composites using X-ray tomography.

- Determination of the spatial distribution of defects at polymer interfaces.

- Study of polymer crystallisation at elevated temperatures using nano-calorimeter and nanobeam diffraction.

- Combination of wide-angle X-ray scattering and fluorescence data to assess the position, size and orientation of particles in carbon nanotube fibres.

- Study of the influence of temperature and deformation on the molecular scale to reveal physical mechanisms behind macroscopic phenomena such as thermal expansion.

CASE STUDY

Company or institute

Massachusetts Institute of Technology

Challenge

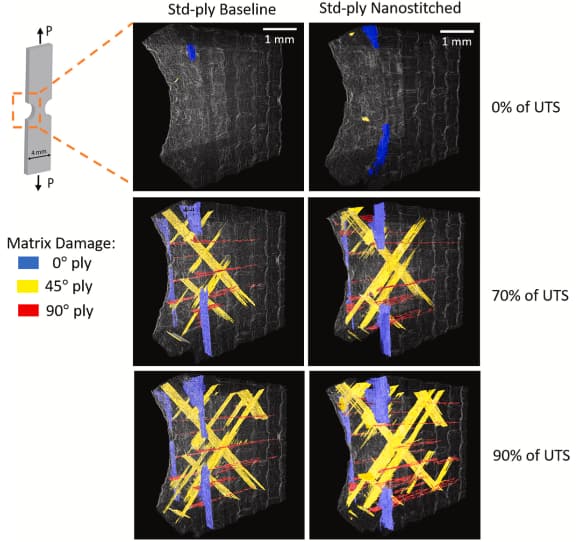

Advanced composite laminates comprised of carbon fibre reinforced plastic (CFRP) are extensively used by the aerospace industry because of their high in-plane mechanical performance and low weight. In this study, researchers wanted to test two technical advancements in composite design, thin-ply composite laminates vs standard ply, and reinforcement of the interlaminar regions with high densities of aligned carbon nanotubes in a hierarchical architecture termed ‘nanostitching’.

Sample

Quasi-isotropic aerospace-grade carbon fibre reinforced epoxy laminates of two different ply thicknesses and reinforced in the interlaminar regions with aligned carbon nanotubes were prepared as double edge-notched tension (DENT) samples for testing in a mechanical loading setup. Samples of 50 mm long by 4 mm wide and 1 mm thick were reduced to 1.8 mm wide in the notched region.

Solution

High-resolution synchrotron radiation computed tomography (SRCT) is a powerful tool to non-destructively characterise the interior of materials. It provides an opportunity to follow 3D damage nucleation and progression in materials under increasing load. At beamline ID19, samples were placed in an in situ loading rig and subjected to uniaxial tensile loading in steps up to 90% of their baseline ultimate tensile strength (UTS). A sub-micron pixel size was chosen to resolve the 7 μm diameter carbon fibres with about 1 μm wide matrix between the fibres. The samples were scanned at various load steps to reveal the damage state progression. Software for three-dimensional visualisation and segmentation was used to classify and quantify dominant damage micro-mechanisms, which were identified as matrix cracking and fibre/matrix interfacial debonding. Although highly significant as a damage mechanism in the eventual catastrophic failure of DENT specimens, delamination was not dominant at loadings up to 90% of their ultimate tensile strenght (UTS).

Benefits

In situ mechanical testing via SRCT proved to be a powerful means to visualise and quantify in 3D the progressive damage within the samples during loading. The 3D surface area of damaged regions could be calculated and used to compare the samples at various steps of loading. Analysis of the results revealed that the thin-ply composites had a significantly lower degree of damage to the standard-ply composites, confirming that the thin-ply morphology reduces damage progression. Furthermore, the carbon nanotube reinforced composites were also resistant to damage and only revealed relatively minor delamination within the limits of this study while providing a 9% increase in ultimate tensile strength over the standard-ply composite.

Reference

In situ synchrotron computed tomography study of nanoscale interlaminar reinforcement and thin-ply effects on damage progression in composite laminates, X. Ni, R. Kopp, E. Kalfon-Cohen, C. Furtado, J. Lee, A. Arteiro, G. Borstnar, M.N. Mavrogordato, L. Helfen, I. Sinclair, S.M. Spearing, P.P. Camanho, B.L. Wardle, Composites Part B: Engineering 217, 108623 (2021); doi: 10.1016/j.compositesb.2021.108623.

Company or institute

Luxembourg Institute of Science and Technology and Goodyear S.A.

Challenge

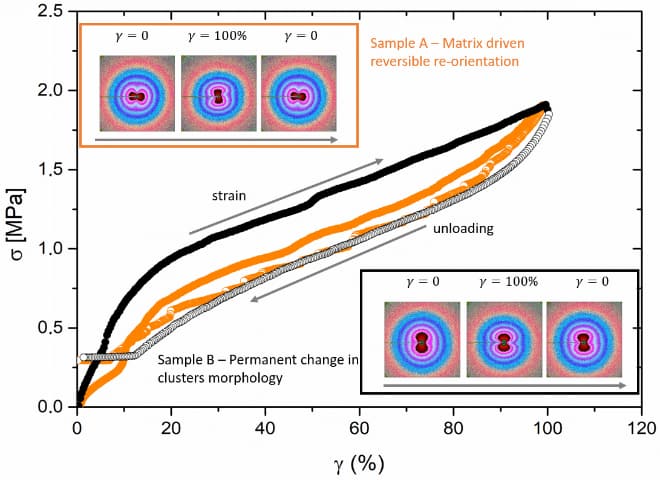

To study changes in the hierarchical microstructure of nanofiller particles in a rubber matrix during deformation.

Sample

Samples were industrially-mixed but simplified rubber composites consisting of silica-filled styrene-butadiene copolymer rubbers, cross-linked but devoid of ZnO (curing activator) to avoid scattering interference from ZnO.

Solution

Ultra-small-angle X-ray scattering (USAXS) at beamline ID02 was used to study the changes in microstructure on a 10 micrometre to 100 nanometre lengthscale while using an in situ stretch-rheometer. The installation of such a device into the X-ray beam, in combination with the high resolution of beamline ID02, allows simultaneous investigation of structural and mechanical properties. The 2D scattering patterns yielded information about the size and distribution of clusters formed by primary particles and relate to the particular stress in the elastomers.

Benefits

The measured scattering functions could be correlated to the evolution of the microstructure of the filler's silica clusters within the styrene-butadiene copolymer rubbers. A scattering model was applied to the orientation-dependent intensities, allowing a quantitative correlation between the external strain and the induced structural changes.

Reference

Hierarchical scattering function for silica-filled rubbers under deformation: Effect of the initial cluster distribution, M. Staropoli, D. Gerstner, M. Sztucki, G. Vehres, B. Duez, S. Westermann, D. Lenoble, W. Pyckhout-Hintzen, Macromolecules 52, 9735-9745 (2019); doi: 10.1021/acs.macromol.9b01751.

Company or institute

Maastricht University/Aachen Maastricht Institute for Biobased Materials and Corbion Purac Biomaterials.

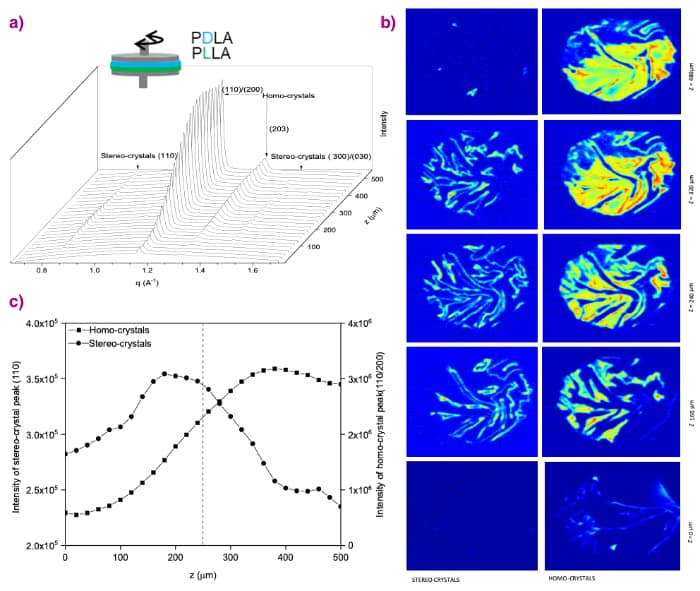

Challenge

Fused deposition modelled (3D printed) poly-lactide polymers have strong layer strength but poor interlayer strength. This study was to test to what length-scales interfacial diffusion of polymers occurs and whether stereocomplexation between polymers of opposite enantiomeric composition in adjacent layers could be used to strengthen interlayer bonding. Stereocomplexation is a phenomenon whereby thermodynamically more stable crystals are formed by the co-crystalisation of equal quantities of enantiomers (D and L forms). With respect to stereo-crystals, polymeric crystals of a single, pure enantiomeric composition (homo crystals) possess a low crystallisation rate and a melting temperature that is about 50°C lower, facilitating mild processing and molecular diffusion across inter-layer welds. This X-ray study aimed to show the degree of stereocomplexation at the interface between two layers of polymers of opposite enantiomeric composition.

Sample

Two stacked disks of opposite enantiomeric composition were pre-compacted and successively molten in a rheometer, using an optimised temperature above the melting point of the individual polymeric samples and mechanically controlling the degree of stereo-crystallinity between the two layers. Stereocrystallisation was followed for 60 minutes, after which the sample was cooled to room temperature inducing homo-crystallisation of the unmixed polymers.

Solution

Wide-angle X-ray diffraction computed tomography at beamline ID15A was used to study the cooled disks. Measurements were performed with a resolution of 20 × 100 × 100 µm3. The tomographic reconstruction based on voxel specific analysis revealed the contributions of the stereo-crystalline, homo-crystalline and non-crystalline phases to the diffraction pattern in three-dimensional space.

Benefits

Diffraction contrast tomography provided unique information about the phases that could not have been obtained through other tomography methods because of the identical density of the phases. The 3D map revealed the extent of stereocrystallisation between phases of opposite enantiomers. The relationship discovered through this research between the time- and length-scales of stereo-crystallisation has been successfully applied to fused deposition modelling, using alternating layers of poly-D-lactide and poly-L-lactide polymers to create mechanically stronger interfacial bonds through controlled physical interlocking of polymer molecules originating from different layers.

Reference

Interfacial stereocomplexation to strengthen fused deposition modeled poly(lactide) welds, V. Srinivas, C.S.J. van Hooy-Corstjens, G.B.M. Vaughan, B. van Leeuwen, S. Rastogi, and J.A.W. Harings, ACS Applied Polymer Materials 1, 2131-2139 (2019); doi: 10.1021/acsapm.9b00421.

Company

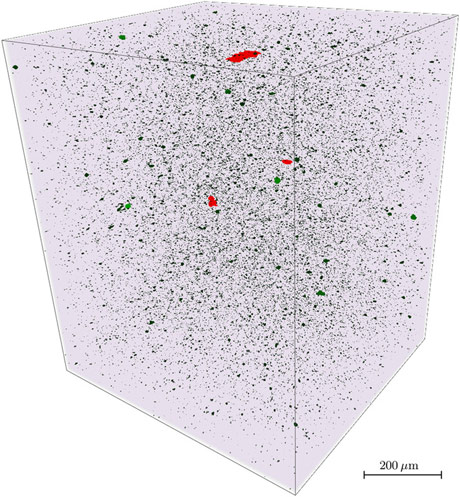

Continental Reifen Deutschland GmbH

Challenge

The challenge was to accurately estimate the size distribution of the macro-dispersion of carbon black filler in a rubber matrix through a synchrotron experiment. This was to provide a high-accuracy 3D reference scan of the bulk material with which to compare the size distribution of the filler particles obtained from a new optical microscopy technique, radiometric stereo microscopy, used to examine the surface of freshly made planar sections, i.e. “fresh cuts”, of rubber, for future use in quality control.

Sample

The sample was a rubber in an early state of carbon black filler incorporation.

Solution

Tomographic data sets were acquired at beamline ID19 using propagation-based phase contrast to enhance contrast between the filler and the rubber matrix.

Benefits

Partially-coherent illumination and phase-retrieval techniques made it possible to exploit the full (complex-valued) refractive index of the materials. The contrast obtained was an order of magnitude better in sensitivity to material changes than the plain attenuation signal. This allowed the different material components to be identified directly in the grey-scaled tomographic image: the rubber matrix as well as the filler particles.

Macro-dispersion of globular filler particles (e.g. carbon black or silica) in a rubber matrix is an important quantity that depends on manufacturing parameters and influences various rubber properties. Therefore, it must be carefully adjusted during the incorporation process and investigated by industrial quality control. The synchrotron experiment provided a benchmark used to gauge the accuracy of radiometric stereo microscopy which would be used for manufacturing quality control of rubber products such as vehicle tyres.

Reference

Estimation of filler macro-dispersion in rubber matrix by radiometric stereo microscopy, J. Ohser, J. Lacayo-Pineda, M. Putman, A. Rack & D. Dobrovolskij, Journal of Microscopy 274, 32–44 (2019); doi: 10.1111/jmi.12782.

Company

University of Manchester and Rolls-Royce

Challenge

Crack propagation in metallic materials is well understood. But aircraft manufacturers are increasingly turning to more complicated composite materials that are lighter, stronger and can operate at higher temperatures. Lower weight reduces fuel consumption, while higher engine operating temperatures allow aeroengines to be more efficient. The challenge is to understand how cracks propagate in such materials.

Sample

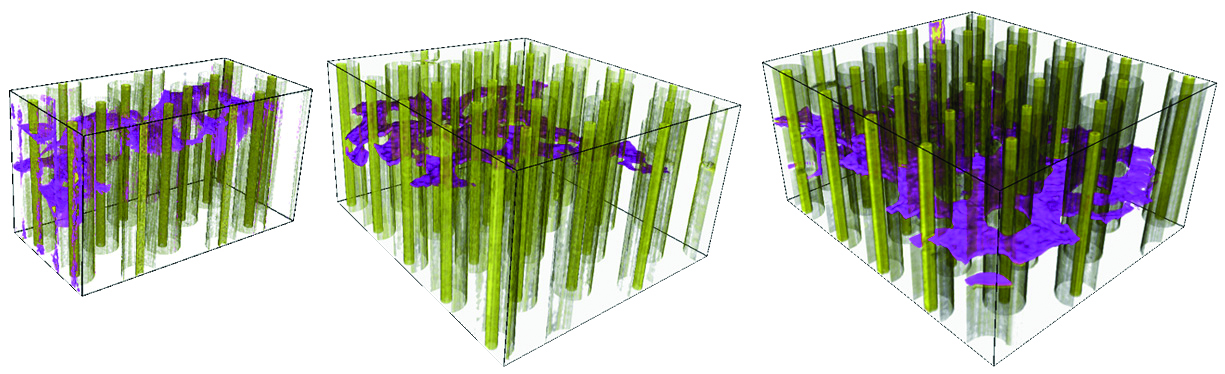

Titanium reinforced with silicon carbide fibres. This composite material can operate at higher temperatures than titanium alone, making it a promising candidate for jet engine parts.

Solution

Electron microscopy reveals the surface features of micro-cracks, but synchrotron X-rays penetrate tens of millimetres into a sample where the behaviour of cracks can be very different. On beamline ID15, scientists can use imaging, to see how cracks grow, and diffraction, which tells them about the local stresses that the cracks grow under.

Benefits

The ability to monitor cracks under load at high temperatures allows researchers to evaluate the potential of these materials under realistic conditions. It also helps to make realistic estimates

of the lifetime of existing components and to design safer, more crack-resistant materials for the future.

Better knowledge of crack propagation transfers directly to other industries in which failure is unacceptable, notably the nuclear industry.

|

|

3D crack-tip microscopy shows a crack (purple) growing in a composite material containing silicon carbide fibres. |