Sample Holder

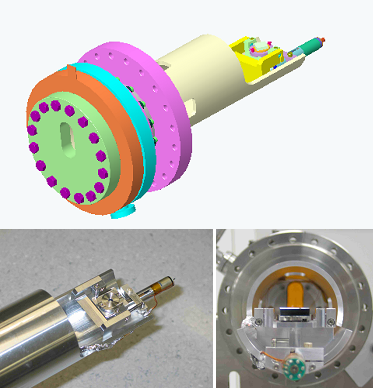

The X-ray alignment of the sample does not require changing the position of the whole chamber. It is performed using a custom designed sample holder and an in-vacuum goniometer composed of an aluminum arm fixed onto the internal face of a flange connected to a rotating feedthrough. Figure 3 (top) shows a perspective view of the sample holder that is mounted on a CF 150 flange with a Lesker rotating feedthrough. It constitutes the basis of the mechanism of our sample manipulator. The arm is holding the sample stage and can rotate it, using the rotating feedthrough, at any angle respect to the incoming particles (atoms/ions). At the sample stage a linear actuator is used to generate an angular tilt of the sample with respect to the incoming X-ray beam (grazing incidence angle), see Fig. 3 (bottom). This motor, vacuum compatible, is presently the only one installed inside the vacuum chamber. The accuracy for the angular positioning is better than 10-3 deg. Calibration measurements demonstrated that the mechanical design allowed generating rotation with an accuracy better than 0.001°.

Figure 3: Sample holder and in-vacuum goniometer

The sample is positioned on a three-point magnet carrier allowing a reliable repositioning (see Figure 3, bottom). To change the sample, one only needs to disconnect the sample carrier unit and to move it in or out of the chamber through a lateral port while the goniometer and the chamber remain fixed. The sample surface is adjusted mechanically at the center of rotation whose position is defined within an accuracy better than a micrometer. The sample is fixed on its holder with colloidal graphite (AGAR – vacuum compatible). This product is a good compromise between its capability to sustain the sample during manipulation and the low residual stress it creates to maintain the sample on the holder.