Detectors

Detection system for in-situ X-ray scattering experiments

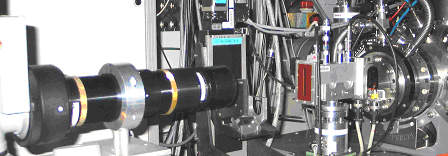

The detection system (Fig. 1.) is a custom one designed for specular and diffuse X-ray scattering measurements and was developed in collaboration with the detector group of the ESRF. It consists of a 2D detector to acquire the scattered intensity and a semitransparent detector to monitor the total intensity of a reflected beam.

Fig. 1. Detection system for real time X-ray scattering measurements

The 2D detector is a cryogenically cooled CCD camera (1024 x 256 pixels of 19 mm size each) coupled to an image intensifier. The front window made of vitreous carbon is followed by P43 phosphor screen, 40 mm thick. Between these two components, a foam layer ensures a good contact between phosphor and entrance of the image intensifier. The X-ray photons stopped by the phosphor screen are converted to visible light a then fiber coupled optically with the entrance window of a reducing image intensifier (demagnification 2.72). The image intensifier consists of a Micro Channel Plate (PROXITRONIC) that is finally lens-coupled to a 16-bit Princeton LN/CCD.

At the maximum recording speed, frames of size 256 x 1024 pixels can be acquired with a gap between the frames in the millisecond range. At the maximum gain of the MCP, single photon detection is achievable. To improve the signal to noise ratio the intensifier output is imaged by a lens system onto the CCD detector that is cryogenically cooled with liquid nitrogen supplied externally with an automatic refilling system. The CCD camera is cooled at –90 °C; its thermal stability is contained within +/- 0.050 °C thanks to a servo control system ensuring the thermal regulation during the experiments. The liquid nitrogen is stored in a Dewar that is enclosed in a vacuum jacket to minimize the consumption. Because of the low operating temperatures, the CCD is operated under high vacuum condition (10-6 hPa). Line spread function measurements yield a spatial resolution of the system of 170 µm.

The CCD camera is connected to an interface card mounted in a PC located in the beamline control room. It can be controlled either from the PC using the PRINCETON's WINVIEW software or from the beamline workstation using SPEC or from both platforms. The use of SPEC is necessary when the CCD is operated in combination with the motion of a motor, e.g., to perform a scan or a macro and to allow the CCD image to be correlated with the monitor count (the transmission detector and/or the direct beam monitor). This is frequently the case when performing in-situ experiments.

Detector Features:

-

Image size: 72.6 mm x 18.2 mm

-

pixel size: 70.9 µm 1024 x 256 pixels

-

Total demagnification: 2.72

-

Line Spread Function: 170 µm FWHM

-

Gain: 2.8-1350 ADU/X

-

CTF: 50% at 2.6 lp/mm

-

Readout noise:

1.9 ADU/pixel (HT=0, t = 0.07 sec)

2.4 ADU/pixel (HT=4, t = 1 sec) -

DQE: 0.71 at 17.4 keV, HT=4, t = 1 sec, level = 23000 ADU

-

Dynamic range: 16 bit