- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2008

- Soft condensed matter

- On-axis microstructural studies of high-performance polymeric fibres

On-axis microstructural studies of high-performance polymeric fibres

Microfocus X-ray diffraction (µXRD) is one of the few techniques that can probe the microstructures within individual polymeric fibres. Until recently, most µXRD studies of single fibres were performed in the standard fibre diffraction geometry. In this geometry, with the fibre perpendicular to the incoming beam, skin-core variations can be investigated based upon the changes observed between diffraction patterns collected at different positions across the fibre diameter. This approach is somewhat limited by the lack of information concerning the origin of scattering elements along the X-ray beam path. This makes it necessary to employ modelling in order to reconstruct skin-core morphologies in detail. Not only does this require a simplification of fibre structure, it risks the introduction of model bias.

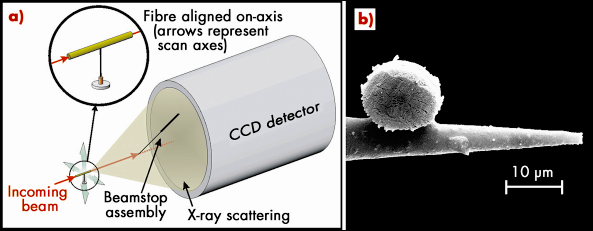

A novel approach to skin-core microstructural studies has been demonstrated recently at the ID13 microfocus beamline. By adopting an on-axis µXRD geometry, skin-core microstructural variations can be imaged directly from within single fibres exhibiting preferred orientation, and without the need for complex modelling. The technique involves carefully aligning a short section of fibre to the beam axis and then collecting diffraction patterns over a two-dimensional area (Figure 55). From the resulting diffraction data it is possible to reconstruct an image of the fibre cross-section based upon different microstructural parameters. For example, point-to-point variations in rotational disorder can be visualised directly between the fibre skin and core whilst the nature of radial crystallographic texture can be studied in detail.

|

|

Fig. 55: a) Schematic of on-axis µXRD geometry and b) Scanning Electron Micrograph of a PpTA fibre section mounted on a glass capillary and viewed on-axis (prepared using a pulsed UV laser cutter). |

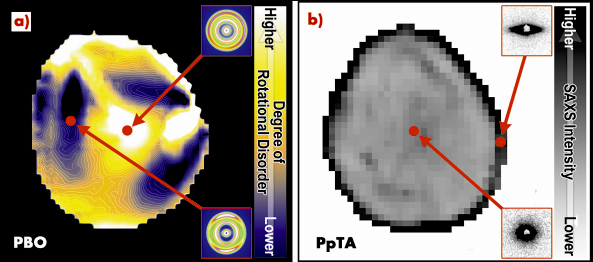

On-axis µXRD experiments on single as-spun poly(p-phenylene benzobisoxazole) (PBO) fibres reveal a microstructure consisting of a relatively disordered skin and core, separated by an intermediate region which exhibits a lower degree of rotational disorder (Figure 56a). The width of the fibre skin appears to vary with position around the fibre circumference whilst the core region is slightly offset from the geometric centre of the fibre. This general skin-core morphology can be explained in terms of differences in coagulation rate and local variations in chain mobility during fibre formation. Structural asymmetry, meanwhile, suggests a heterogeneous coagulation environment.

|

|

Fig. 56: a) Skin-core variations in rotational disorder for PBO fibre and b) variation of SAXS intensity over PpTA fibre cross-section. Individual diffraction patterns are shown inset. |

High performance fibres, like many other materials, have hierarchical microstructures. It is therefore also necessary to consider structural features which may exist over larger length scales when investigating skin-core morphologies, such as those accessible to small-angle X-ray scattering (SAXS). On-axis SAXS experiments on single poly(p-phenylene terephthalamide) (PpTA) fibres reveal variations in SAXS between the fibre skin and core (Figure 56b), and differences between fibres having different processing histories. Following fibre spinning, the skin region contains elongated structures aligned parallel with the fibre’s edge whilst the remainder of the fibre exhibits an isotropic SAXS pattern indicative of randomly oriented or cylindrical scattering elements. Following heat treatment, SAXS is reduced in all but the very core of the fibre. This suggests that, like coagulation, structural modification due to the heat treatment process may also occur heterogeneously.

Aside from skin-core microstructural variations, the on-axis µXRD geometry also allows radial crystallographic texture to be investigated in detail. Both PBO and PpTA fibres are found to exhibit this type of preferred orientation over their entire cross-sections. A model has been developed which allows azimuthal scattering profiles to be calculated for specific hk0 reflections under an on-axis geometry. By minimising the model against diffraction data, the nature of radial crystallographic texture can be probed. The results reveal that, for as-spun PBO, the a* unit cell axis is offset from the fibre radial direction by 23°. This angle corresponds to an almost radial arrangement of the highly planar PBO molecules. This suggests that solvent outflow during coagulation is at the origin of the radial crystallographic texture. In an edge-on arrangement, the PBO chains have the lowest drag coefficient.

Adopting an on-axis µXRD geometry has revealed many new microstructural features for high performance fibres whilst allowing previously known features to be examined in greater detail or confirmed from model predictions. The interest in characterising such microstructures is considerable. Not only are they thought to influence fibre mechanical properties, they can also dictate the interfacial performance of composite materials. If these complex structure-property relationships can be elucidated, it could provide a cost-effective way to tailor fibre properties during manufacture whilst opening the door to producing the super-fibres of tomorrow.

Principal publications and authors

R.J. Davies, M. Burghammer, C. Riekel, Macromol. 40, 5038 (2007); R.J. Davies, M. Burghammer, C. Riekel, J. Appl. Crysta. 41, 563 (2008); R.J. Davies, C. Koenig, M. Burghammer, C. Riekel, Appl. Phys. Let. 92, 101903 (2008).

ESRF