- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2007

- The Accelerator and X-ray Source

- Cryogenic in-vacuum undulator development

Cryogenic in-vacuum undulator development

A cryogenic permanent magnet undulator (CPMU) has recently been developed. The advantage of the CPMU comes from the increased remanence and coercivity of NdFeB magnetic material at low temperature. The increased remanence results in a proportionally increased undulator magnetic field while the increased coercivity results in an improved resistance to demagnetisation following exposure to an electron beam [1]. As the temperature is reduced the remanence increases and reaches a maximum of around 140 K when a spin reorientation transition (SRT) takes place. Ultimately, a fully optimised CPMU should provide a field enhancement of around 30% over conventional room temperature in-vacuum undulators.

A full-scale prototype has been constructed. The device has a period of 18 mm and a magnetic length of 2 m. It corresponds to a modified version of a standard ESRF in-vacuum undulator. The grade of the magnet material was selected to allow full baking at 120°C, but has resulted in a limited field enhancement. The goal was to develop the technology and field measurement system while minimising the risks, making sure that the undulator can be safely operated on the ring. The high precision magnetic measurement system needs to be operated under vacuum with magnetic assemblies at cryogenic temperature. Figure 147 shows the CPMU undergoing field measurement. The measuring bench includes a fast scanning Hall probe and a stretched wire system for the measurement of the field integral components. Both systems are implemented using a vacuum chamber specifically built for such a purpose.

|

|

Fig. 147: The CPMU undergoing magnetic measurements. |

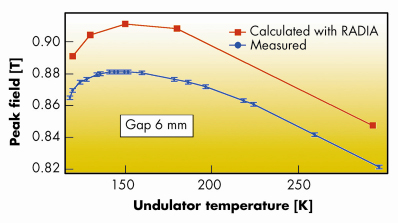

The measuring bench has all the required motorisation outside the vacuum. The associated motions are transmitted either by magnetic coupling (Hall probe bench) or by mechanical connection through bellows (stretched wire bench). The local field measurements are performed at a constant speed (30 mm/s) while reading the three field components at 100 micrometre steps along 2.4 m long scans. The longitudinal positioning accuracy is based on laser interferometers tracking both the position and the pitch angle of the moving hall probe carriage. Figure 148 shows the peak field of the undulator at different temperatures for a gap of 6 mm. It reveals the maximum connected to the SRT and compares favourably with the prediction of non linear models performed with RADIA. The RADIA model has been developed following the magnetic characterisation (B vs H) of the NdFeB samples as a function of temperature. The magnetic measurements confirm the predicted temperature for maximum field (around 150 K for the prototype). The 4% discrepancy between the measured and predicted peak field vs temperature can be explained by an offset in the magnetic gap measurement.

|

|

Fig. 148: Measured and predicted peak field versus temperature for the CPMU with a gap of 6 mm. |

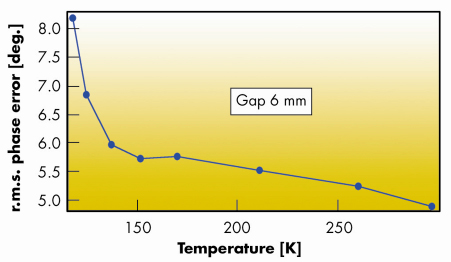

Figure 149 presents the rms value of the optical phase error computed at each pole of the undulator. The phase error is directly connected to the X-ray spectrum quality of the device. The observed change of phase error between room temperature and 150 K is due to a residual temperature gradient along the undulator assembly.

|

|

Fig. 149: Measured rms phase error versus temperature for the CPMU. |

The cooling system is a liquid nitrogen closed loop which is identical to the system adopted at ESRF for the cooling of cryogenic monochromators.

To achieve the targeted temperature of 150 K at the magnetic assembly, the connection between the cooling channels and the magnetic assembly is done with distributed flexible copper spacers providing the necessary temperature drop. Such a cooling system is well adapted for this type of long device both in terms of cooling efficiency and running costs. The typical measured heat budget is 150 W when the undulator assembly is at 150 K. The prototype will be installed in the ID06 straight section during the Christmas 2007 shutdown.

Reference

[1] T. Hara et al., Phys. Rev. Spec. Top. Accelerators, and beam, Vol. 7 (2004).