- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2005

- X-ray Imaging and Optics

- Diamonds for Modern Synchrotron Radiation Sources

Diamonds for Modern Synchrotron Radiation Sources

The trend in modern X-ray sources, third (and eventually fourth) generation storage rings or free electron lasers, is towards higher brilliance, with more photons, out of smaller optical source sizes, in smaller solid angles and within shorter pulses. This may lead to high power densities, exceeding hundreds of watts per square millimetre on the first beam optical elements. These elements can be filters, windows, polarisers (phase plates), beam splitters or monochromators.

The preferred material for Bragg diffracting elements is, at present, silicon: it can be grown to a very high crystal perfection and workable size as well as rather easily processed to the required surface quality. These elements preserve the transversal coherence in the X-ray beam, which is important for phase-sensitive imaging techniques and for advanced focusing possibilities. However, in comparison to silicon, diamond has a number of advantages for X-ray optical applications. Its linear absorption coefficient, at 8 keV, is about 10 times lower, and its thermal expansion coefficient at room temperature is about 2.4 times lower than that of silicon. The thermal conductivity at room temperature is from 4 to 23 times higher, depending of the type of diamond considered. These parameters lead us to prefer diamond for many X-ray optical applications, provided that large, nearly perfect crystals are available. So far, this has not been the case.

To improve this situation a collaboration between Element Six Technologies (Johannesburg, South Africa), the University of the Witwatersrand (South Africa) and the ESRF was established to coordinate and intensify their effort to develop diamond based X-ray beam optical elements for third and fourth generation X-ray sources.

The necessary single crystalline quality may only be achieved with synthetic material. Basically two classes of growth methods are presently used, chemical vapour deposition (CVD) and high-pressure high-temperature growth (HPHT), the last one being the most promising for X-ray optics applications.

|

|

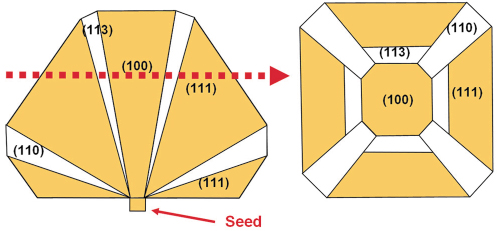

Fig. 141: Growth sectors seen most frequently in the growth of near cubo-octahedral HPHT diamond crystals of type Ib (left). The growth face orientations are indicated. View from above after a cut along the red arrow (right). |

The main results may be summed up as follows:

a) The faster growing type Ib material (for many years assumed to be the best candidate for high perfection) with a nitrogen content of a few hundred parts per million and in the required size of 4 to 8 mm2 is of too low quality. Only selected samples of that type may be used for less demanding applications like phase plates (Figures 141 and 142).

|

|

Fig. 142: Optical image (left) and X-ray white beam topograph (right) of a type Ib diamond plate, showing the inhomogeneous distribution of nitrogen and correlation with strong strain fields due to the growth sector boundaries (as sketched in Figure 141), as well as dislocations. The nitrogen concentration is higher in the brown sectors of the optical image. |

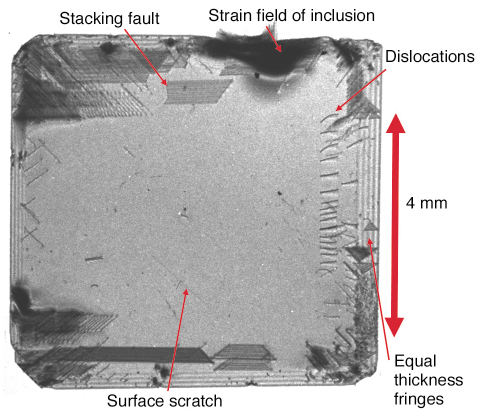

b) Highly pure (very low nitrogen content) type IIa diamond crystals may be grown with a perfection that is approaching the quality required for the more demanding applications such as X-ray imaging and in particular X-ray imaging with coherence preservation (Figure 143).

|

|

Fig. 143: X-ray white beam topograph of a type IIa diamond plate, showing a homogeneous central region and some typical defects and effects that may be present. No strain fields related to growth sector boundaries are visible. |

c) Double crystal topography experiments (in reflection geometry) in a setup with a very low estimated detection limit for weak strains of about 10-7 showed no strain above that limit in the high quality crystal regions.

d) Rocking curve measurements carried out with a high-resolution setup showed negligible or only small increases (0.0” … 0.2”) of local reflectivity curve widths (1”) after extraction of the apparatus function (width about 0.15”).

e) For a coherence preserving crystal, both the bulk and the surface quality must be sufficiently high. The material we studied so far was of high bulk quality. The current best surface finish obtained by mechanical polishing was measured on a type Ib sample, a value of 0.3 nm rms was obtained. Type IIa crystal plates have not yet been polished to that quality, the best value was 0.96 nm rms. In the best case, the effective angular source size increased by only 1.1 to 2.5 times. As soon as samples with the full surface processing (and lower micro-roughness) arrive, these measurements will be continued.

Consequently the targets for further development of the type IIa diamond are the increase of its size, a crystal perfection pushed to its limits, and a high quality surface processing.

Authors

J. Härtwig (a), P. Van Vaerenbergh (a), I. Gierz (a), J. Hoszowska (a), A. Rommeveaux (a), A. Chumakov (a), G. Carbone (a), S.H. Connell (b), M. Rebak (b), R. Setshedi (b), D. Dube (b), L. Mkhonza (b), R. Burns (c), J.O. Hansen (c).

(a) ESRF

(b) University of the Witwatersrand, (South Africa)

(c) Element Six Technologies, Johannesburg (South Africa)