- Home

- News

- Spotlight on Science

- Metallic glass foam:...

Metallic glass foam: a macroscopic glass model?

08-11-2007

The intriguing nature and unique physical characteristics of the glassy (amorphous) state has captivated condensed matter physicists for several decades. Over the years, several hypotheses have been conceived by theorists seeking to identify the fundamental structural origin of the characteristic features exhibited by these materials.

Some of the most noteworthy phenomenological ideas can be found in a monograph by Alexander [1]. Alexander visualised the glassy structure as a “floppy-bonded network prone to buckling when stressed”. In his view, the nonaffine distortions in glasses arise due to the randomness of the glassy nanostructure, and can be correlated to “percolating atomic chains effectively acting as structural buckling membranes”. In a microtomography study performed recently, the characteristic glassy-like elastic features were also found to arise in macroscopic highly-random cellular structures, where buckling-prone intracellular membranes dictate the rigidity of the structure.

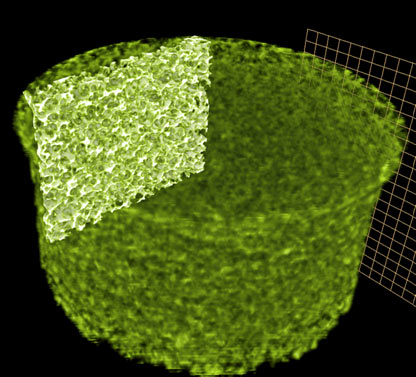

Researchers from the California Institute of Technology, the Oklahoma State University, the ESRF, the Institut National Polytechnique de Grenoble and the Iowa State University, used real-time X-ray microtomography to study the yielding mechanisms of a highly-random metallic glass foam. They examined the structural cell deformations within a bulk foam specimen in situ upon loading at beamline ID15A (Figure 1). A cylindrical loading fixture specifically built for microtomography experiments with a maximum loading capacity of 7.5 kN was utilised. A strain rate of 2×10-5 s-1 was applied. A cycle involving compressive loading towards a non-catastrophic collapse event (at approximately 100 MPa) followed by unloading was implemented. Eighteen tomographic datasets of the cellular deformed structure were recorded. The results of their investigation were published in the August 1st issue of Advanced Materials.

|

|

|

Figure 1: 3D-rendered view of the cellular structure prior to loading. |

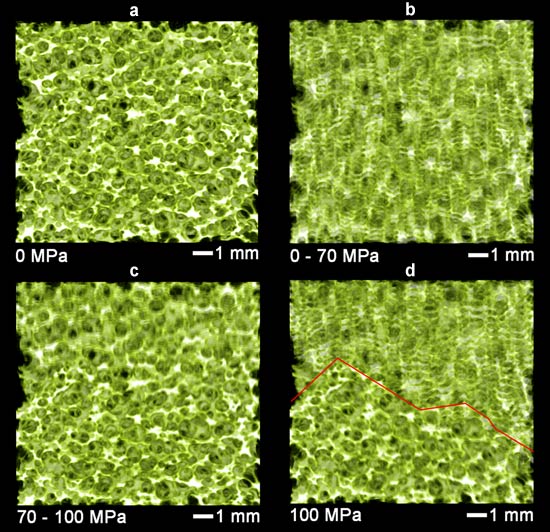

By analysing the recorded tomographic data the scientists found that the yielding of the foam is accommodated by a sequence of randomly evolving membrane-buckling instabilities (Figure 2). By carrying out a shear stability analysis utilising data for several metallic glass foams of varying porosity, they discovered that these cellular structures obey the same universal shear stability threshold as zero-temperature glasses of varying elastic constants. The authors interpreted this resemblance as evidence of universality in the percolation of shear rigidity, effectively associating the membrane-buckling instabilities in a highly-random cellular structure with the unstable shear-phonon modes in a glass. In conclusion, the result of their investigation suggests that the metallic glass foam is an experimentally accessible and statistically accurate macroscopic model for the response of a real glass to applied loads.

Reference

[1] S. Alexander, “Amorphous solids: their structure, lattice dynamics and elasticity”, Physics Reports 296, 65-236 (1998).

Principal Publications and Authors

M.D. Demetriou (a), J.C. Hanan (c), C. Veazey (a), M. Di Michiel (d), N. Lenoir (e), E. Üstündag (b), and W.L. Johnson (a), “Yielding of metallic glass foam by percolation of an elastic buckling instability”, Advanced Materials 19, 1957-1962, (2007).

(a) Keck Laboratory, California Institute of Technology, Pasadena (USA)

(b) Materials Science and Engineering, Iowa State University, Ames (USA)

(c) Mechanical and Aerospace Engineering, Oklahoma State University, Tulsa (USA)

(d) ESRF

(e) Laboratoire 3S, Grenoble (France)