- Home

- Experimental Hutch 1 - EH1

Experimental Hutch 1 - EH1

Description

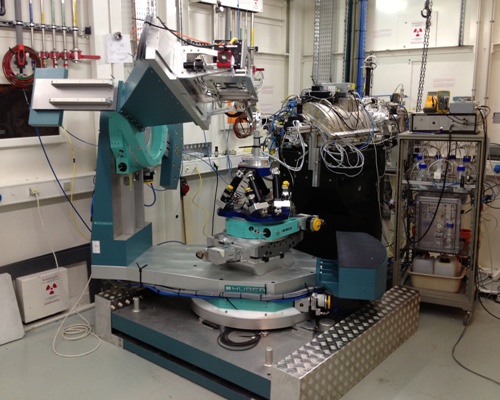

The first hutch contains a vertical geometry z-axis diffractometer that can accommodate small user’s chambers (UHV equipments, electrochemical cells, etc). The new diffractometer was installed last May 2012 and the sample positioning is made by a hexapod similar to the one in EH2 (see picture). The equipments (chambers, cells) can be installed on top of this hexapod.

New EH1 Diffractometer (May 2012)

This station is dedicated to surface characterization during reactions (catalysis, electrochemistry, etc.).

There are three different reactors available for users:

1. A batch reactor with a gas line system

2. A batch reactor for harsh conditions

3. A flow reactor with a remote controlled gas system

4. An electrochemical cell set up with automatic control of valves and gases

Batch reactor

Small UHV chamber with a 360° beryllium window. The UHV equipment and a turbo pump are located on the chamber upper part to leave a wide solid angle for exploring reciprocal space. The reaction (chamber) part can be sealed off with a gate valve.

It is equipped with:

- Ion sputter gun (PHI-Perkin Elmer) for sample preparation

- Residual Gas Analyser, RGA

- Leak valve for gas introduction

- Several pressure gauges for different pressure ranges

- Sample mounting on a boralectric heater with a thermocouple type K or E attached to the sample holders. Sample annealing possible up to 1400K. For oxygen rich conditions, Tmax = 800K

Batch reactor

Batch reactor for harsh conditions

Special batch reactor to handle corrosive gases with a cylindrical 360° aluminum window 1 mm thick. This imposes to work with photon energies above 20 keV. UHV equipment and turbo pump are located on the lower chamber part. On the upper part electron beam evaporators and the ion sputter gun can be installed. Corrosive gases such as HCl or H2S can be used. It is also possible to install a HCl trap on the gas exhaust pipe of the pump.

It is equipped with:

- Ion sputter gun (PHI-Perkin Elmer) for sample preparation

- Residual Gas Analyser, RGA

- Leak valve for gas introduction

- Several pressure gauges for different pressure ranges

- Sample mounting on a boralectric heater with a thermocouple type K or E attached to the sample holders. Sample annealing possible up to 1400K in UHV. For oxygen rich conditions, Tmax = 800K

Harsh conditions reactor

Flow Reactor

Recently a flow reactor (called UFO Chamber) was designed and constructed with in-situ UHV surface preparation tools and is already available for users. This chamber allows the study of reactions in real time and closer to real industrial conditions. An upgraded gas line is available using an automated system of gas flow controllers. This improves the data acquisition procedure and gives the ability to follow the catalytic reaction from the beginning.

The flow reactor (UFO Chamber) has a lower and an upper part. The lower part is the UHV section whose upper big flange is holding the UHV tools and is equiped with:

- Ion Sputter Gun (SPECS) for sample surface preparation

- Residual Gas Analyser, RGA

- Electron beam evaporator (Omicron)

The big flange can be moved up and down with respect to the sample position. When up, the sample is in UHV conditions and can be prepared with standard UHV tools. When the flange is down the region around the sample is sealed off having a small reactor volume (15 mL). Gases can flow through two capillaries. UHV conditions are preserved in the bottom section all the time.

Flow Reactor (UFO Chamber) Top View

Flow Reactor (UFO-Chamber) on top of EH1 Diffractometer inside EH1

Flow reactor gas system

The gas system has four mass flow controllers at the gas inlet. This allows mixing exact proportions of desired gases. It is remote controlled via SPEC (BL control software).

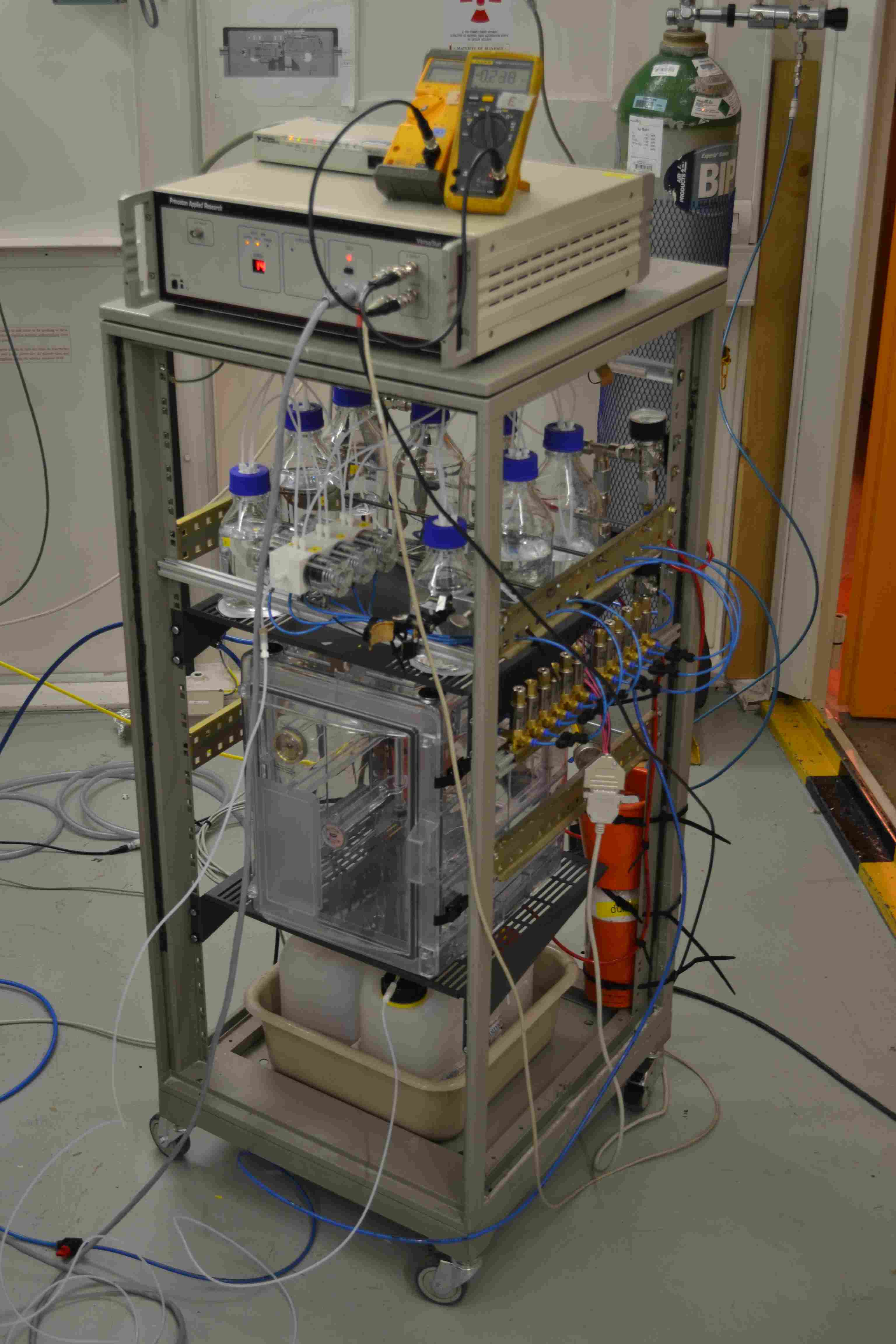

Electrochemical setup: cell and valves control system

The electrochemical setup was developed to monitor in real time the structure of electrochemical solid-liquid interfaces with atomic resolution. The setup includes the electrochemical cell and the liquid-gases rack (see pictures below). This flow electrochemical cell allows to carry out surface diffraction experiments while controlling the applied potential with the possibility of exchanging the electrolyte solution. The equipment is a robust design, which allows stable potential control and fast exchange of chemical solutions and consequentlly to study chemical and electrochemical processes difficult to investigate with other techniques. In the flow management arrangement, the solutions can be exchanged with a zero dead volume valves system (rack), specifically designed to avoid sample and solution contamination. Furthermore, the system allows to switch the solutions during the experiment without loosing the potential control on the sample. The possibility to exchange the solution in the cell can be useful for a sample surface preparation and cleaning. Chemical and electrochemical treatment of the sample surface can be done directly in the cell, avoiding any exposition of the sample surface to air and thus preserving it from any possible contamination.

Ref. Carla et al, 221st ECS Meeting, © 2012 The Electrochemical Society

Electrochemical cell

Electrochemical valves setup (rack)

Focusing the X-rays beam

A Kirkpatrick-Baez (KB1) mirror system is installed in EH1 for focusing the beam at the sample in the micron range.