- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2009

- Accelerator and X-ray Source

- A renovated linac pre-injector system

A renovated linac pre-injector system

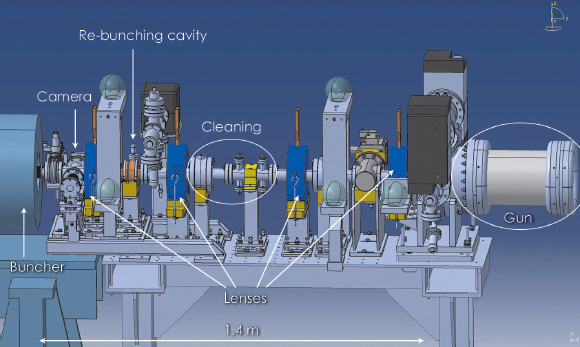

The 6 GeV electrons injected into the storage ring are accelerated by a chain of accelerator systems known as the injector system. The main components of the injector include a linear accelerator which accelerates the electrons from 90 keV to 170 MeV and a booster synchrotron which accelerates the electrons from 170 MeV to 6 GeV. The 90 keV electron beam injected into the linear accelerator is produced by a thermoionic triode electrostatic gun. A few years ago, the manufacturer of the cathodes specific to our gun design discontinued the production of these cathodes. These cathodes are rather fragile and over time lose emissivity; they need to be replaced at regular intervals. The ESRF was therefore forced to re-examine its long term strategy concerning the linac gun. The opportunity was taken to improve the gun and transport system. The chosen transport system is very similar to that developed by Thales for SOLEIL. It makes use of a triode gun design initially built for the CLIO facility at Orsay. The layout of the new gun and transfer line is shown in Figure 160. The removal of the old gun and transfer line and the installation and commissioning of the new one, including the control system, was carried out in less than three weeks during the August 2009 shutdown. Since then, the new pre-injector system has been in permanent operation.

The electrons are emitted from a heated cathode and accelerated up to 90 KeV by a DC electric field. The current emitted by the cathode is controlled through a voltage applied to a grid located next to the cathode. The electron beam produced is transversally focused by the accelerating electric field in the gun as well as by four solenoid lenses spaced regularly along the transport line (shown in blue in Figure 160). Two vertically deflecting electrodes and one iris are installed between lens 2 and lens 3 (for beam cleaning). A pre-bunching RF cavity has been installed between lens 3 and 4 (for an increased capture in the linac RF field). Finally a retractable fluorescent screen has been added after lens 4 aimed at imaging the electron beam before it enters the buncher cavity (22 cell standing wave RF structure operating at 3 GHz) of the linac. Horizontal and vertical steerer coils are located in each of the four lenses. The main engineering difficulties involve the association of the high voltage needed for the acceleration in the gun, the fast pulsing of the cathode, grid and plate deflection to control the electron pulse duration and the 3 Ghz radio frequency field required for the pre-bunching cavity. Indeed, the electromagnetic compatibility of the different components has to be carefully optimised.

|

|

Fig. 160: Mechanical layout of the new pre-injector system. |

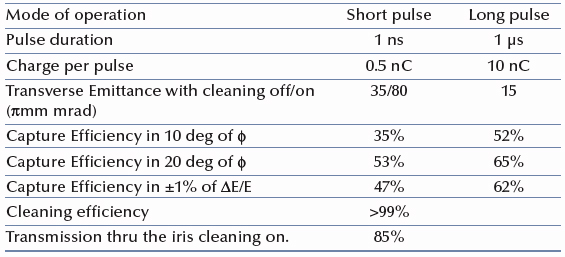

Table 6 shows the predicted performance of the new gun and transport system in both the short and long pulse mode of the linac operation.

While a number of the parameters predicted in Table 6 still need detailed experimental confirmation, the initial results are in line with the predictions. It has been observed that the pre-bunching cavity enhances the capture process by a factor of two. A total transfer efficiency of 60% between the beam generated in the gun and the beam captured in the booster synchrotron has been recorded in short pulse mode (0.4 nC , 1 ns).

|

|

Table 6: Performance of the new gun and transport system calculated from simulation. |

The transverse deflecting electrodes allow the deflection of the electron emitted by the cathode with the wrong timing in such a way that a single bunch of high purity can be captured at 352 Mhz in the booster ring before it is sent into the storage ring. This process of improving the purity in a single bunch (cleaning) is essential for some beamlines requiring special filling patterns in which a very high contrast ratio between the main and adjacent pulses is mandatory. By sending a 700 V pulse with 1.5 ns FWHM duration, it has been possible to improve the bunch purity of the previous gun by more than two orders of magnitude.

Reference

[1] T. Perron, E. Rabeuf, E. Plouviez, V. Serriere, A. Panzarella and B. Ogier, EPAC’08, http://accelconf.web.cern.ch/AccelConf/e08/papers/wepc087.pdf.