- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2014

- Enabling technologies

- Generic solutions ease the way for Phase I upgrade beamlines

Generic solutions ease the way for Phase I upgrade beamlines

In 2009, the ESRF took on the challenge of designing, installing and commissioning nine upgrade beamline projects (UPBL), renovating four beamlines and moving three beamlines. Eighteen endstations of considerable complexity, in comparison with existing beamlines, were to be completed in the six years of the upgrade Phase I using existing technical staff. A strategy of using standard and generic building blocks to construct the beam delivery and detection systems yielded significant technical and financial advantages, leaving time to develop ad hoc sample environment and manipulation instrumentation.

Advantages to generic solutions:

- Technical staff are interchangeable between projects as the technology adopted is similar leading to easier maintenance, lower ownership costs and quicker commissioning.

- High performance is obtained thanks to intense design and testing efforts invested to optimise and characterise the first units of each generic block, which then benefits all the devices using this block.

- Design and development time is considerably shorter. A more collaborative approach to design work is fostered due to multiple use of the same technology.

- Cheaper and more efficient procurement due to increased quantities of component building blocks with appropriate sub-contractors being identified early in the development phase.

- The combined performance of the beamlines and accelerator can be optimised due to the global view and know-how of the engineers and technical staff over the whole ESRF complex.

There are several minor disadvantages such as:

- Longer design and production time for the first device of the generic family.

- Less freedom for beamline scientists and engineers to choose their individually-preferred and specifically tailored solutions.

Generic solutions at the ESRF originated from the time of the installation of the first beamlines in the 1990’s. Then, being the first third generation synchrotron source, the ESRF was obliged to develop a large proportion of its instrumentation in-house as industrial suppliers had not enough experience to produce cutting-edge designs. This initial investment in our in-house engineering and the early adoption of standard components such as primary and secondary slits, fluorescent screens, attenuators, beamshutters, DPAP motor controllers, SPEC, TACO, Kohzu monochromators, etc., allowed the first beamlines to be installed and commissioned efficiently. As the source performance improved and increased in power in the late 1990’s, these initial, rather basic, components, which were essentially identical for all beamlines, were gradually replaced with higher performance versions either for standard devices (e.g. primary slits and attenuators) or by generic variants that were tailored or adapted to individual beamline requirements.

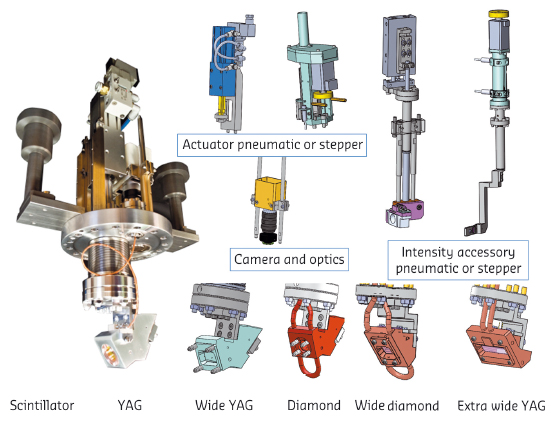

A generic solution is considered to be an instrument that can be made up of building blocks which have already been used and tested beforehand with a number of relatively small changes introduced for the particular beamline. A typical example of this would be the ESRF UHV compatible beamviewers that have evolved from their initial concepts starting in 1993 to a stable design in 2012. These devices are particularly being used during the commissioning phase of beamlines, and hence, large quantities were foreseen for Phase 1 of the upgrade (Figure 151).

|

|

Fig. 151: UHV Beam viewers. |

The beamviewers consist of the following building blocks:

- Camera and focusing optics

- Scintillator and holder

- Positioning device to bring the viewer into or out of the beam

- Vacuum chamber

- Software to read, analyse and display the images

Basic imaging cameras are evolving quickly and the necessity to choose a standard camera for Phase 1 beamlines was identified early on. An Ethernet GigE camera was chosen and implemented in a number of different ESRF devices. The scintillator and its holder depend on the beam characteristics (white/pink/monochromatic, size and position) and consequently each beamline is able to choose either a standard configuration or one adapted to its needs. Two methods of positioning the device in the beam are available either pneumatically or using a stepper motor driven actuator. Integration of the device is specific to the beamline, and hence, the vacuum chamber is designed on an ad hoc basis. The ESRF software group is confronted daily with integrating images into beamline control so the beamviewers naturally benefit from LIMA (Library for image acquisition) developed as a generic solution for reading cameras. A total of more than 50 devices from this family have been installed during the Phase 1 beamline programme.

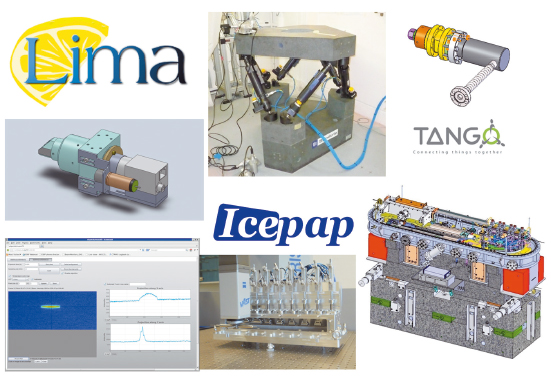

The catalogue of generic solutions has continued to grow during Phase 1, which started with some high performance ESRF solutions ranging from opto-mechanics such as dynamic benders for KB mirror systems and precision jacks through more general mechanics such as hexapods and positioning technology (Figure 152). The generic approach extended to control instrumentation such as IcePAP motor controllers or MUSST acquisition modules, Xray detectors such as the FReLoN cameras and the first generations of Maxipix devices. and software solutions with libraries (PyFAI), applications ( MxCube, PyMCA), and complete toolboxes (TANGO). In addition, all generic software is open source and has been shared with a large number of sites in Europe and the rest of the world.

|

|

Fig. 152: Generic solutions. |

These generic solutions have been extensively used during the upgrade and are now complemented among others by:

- Opto-mechanics: A range of white beam and monochromatic beam transfocators, fixed radius nano focusing KB systems, white beam mirror assemblies and multilayer monochromators.

- Mechanics: Improved hexapods.

- Diagnostics and detectors: extended range of focused beam viewers, new high resolution scintillator screens or CdTe based Maxipix detectors.

- Control electronics: continued improvements of IcePAP motor controllers and 100 MHz voltage-to-frequency converters.

- Software: TANGO, LIMA, MxCube, PyFAI, PyMCA, e-motion, graphical user interfaces, workflows, metadata and archive databases.

Authors

T. Mairs, R. Barrett, Y. Dabin, P. Fajardo, A. Goetz and P. Marion, representing the many engineers and technicians of the ISDD who worked on the generic solutions.

ESRF