- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2003

- Industrial and Applied Research

- Damage in Metals Studied by High-resolution in situ Tomography

Damage in Metals Studied by High-resolution in situ Tomography

Metallic materials are widely used because of their structural properties. When examined carefully and at the micrometre scale, they are found to be heterogeneous. Even if their volume fraction is low, the heterogeneous regions, hereafter called "inclusions", play a key role in the rupture of metallic materials.

This rupture is due to a damage process which is composed of different phases:

- Damage initiation by cleavage of the inclusions, by inclusion/matrix interface decohesion or by matrix cracking around the inclusions

- Damage extension

- Damage linkage by coalescence and the percolation of a macroscopic crack between the initiation sites

The different phases of this process have been studied more theoretically than experimentally. Moreover, existing experimental studies were performed by non-destructive surface or by post-mortem destructive observations. None of these two methods allows a perfect quantification of damage.

The aim of the present work was to bring a unique experimental contribution to the characterisation of damage in model materials by using high-resolution X-ray attenuation tomography on the ID19 beamline.

|

|

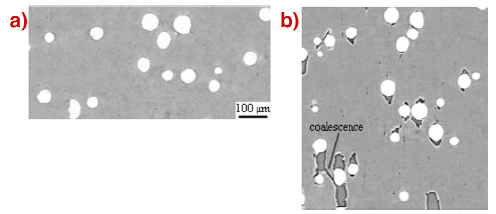

Fig. 155: Two slices extracted from a tomographic reconstruction of a) initial, and b) deformed states of the soft matrix model Aluminium/ceramic composite showing damage initiation, extension and coalescence. |

|

|

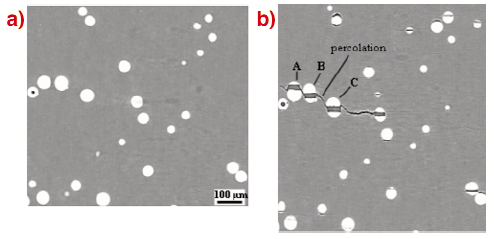

Fig. 156: Same as Figure 155 for the hard matrix composite. |

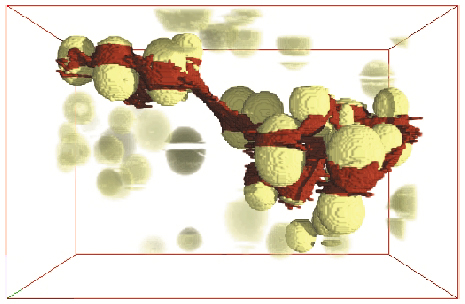

X-ray tomography has been coupled with in situ tensile tests to study the damage mechanisms in different model materials at a voxel resolution of 2 µm. The samples were produced specifically for the study. They consisted of two different aluminium matrices (a soft pure aluminium and a hard 2124 aluminium alloy) each containing 4% of spherical hard ceramic particles. The samples were loaded and scanned at increasing values of the plastic strain. The damage mechanisms could be clearly imaged and analysed from these experiments. Figures 155 and 156 show the initial (a) and the final (b) stages of the two materials reinforced with 4% of inclusions i.e. the soft (Figure 155) and the hard (Figure 156). These images show the damage initiation, growth and then coalescence stages in the hard and soft materials. The difference between the two is the nature of the initiation mechanism: inclusion/matrix decohesion for the soft and inclusion cleavage for the hard material. Figure 157 shows a 3D visualisation of a large crack percolating between microcracks. The breakthrough compared to classical studies is that these two damage initiation mechanisms could be quantified very precisely and without any possible ambiguity from these 3D images [1]. This quantification is, to our knowledge, the first unambiguous one attempted on materials with such a controlled microstructure. This allowed us to analyse the classical models widely used in this field, in the light of new experimental results.

|

|

Fig. 157: Three-dimensional view of the same region as that shown in Figure 156 with the particles concerned by the percolation of the crack. |

It is usual in this field of materials science to try to define damage initiation criteria which will help to predict the rupture of materials. The main damage initiation criteria developed so far in the literature were compared to our experimental results. It was shown that the normal stress and the stored elastic energy in the inclusions were the best two criteria. The intrinsic properties of our inclusions were inversely calculated from the comparison between our experimental results and finite-element calculations. The distribution of the rupture stresses in the different particles was well described by a Weibull type expression.

We have also studied damage growth [2]. Compared to the classical Rice and Tracey [3] type predictions for this mechanism we found that:

- There is a threshold for the growth of previously initiated voids

- Growth is delayed by the initiation stage

- The growth rate is scattered from one void to the other, the Rice and Tracey prediction providing an upper bound estimation for this rate

For these various reasons, the overall damage growth rate is much slower in our materials than in the predictions. This new information is an important result in the field and suggests to further study the phenomenon with this kind of technique.

References

[1] L. Babout, W. Ludwig, E. Maire and J.Y. Buffière, Nuclear Instruments and Methods in Physics Research B, 200, 303 (2003).

[2] L. Babout, E. Maire, J.Y. Buffière and R. Fougères, Acta Mater., 49, 2055 (2001).

[3] J.R. Rice and D.M. Tracey J. Mech. Phys. Solids, 17, 201 (1969).

Authors

E. Maire (a), L. Babout (a), P Cloetens (b).

(a) INSA Lyon (France)

(b) ESRF