- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2005

- X-ray Imaging and Optics

- New Insight into the Mechanisms of Liquid Metal Embrittlement by X-ray Projection Microscopy

New Insight into the Mechanisms of Liquid Metal Embrittlement by X-ray Projection Microscopy

The penetration of liquid gallium into the grain boundaries of aluminium alloys is known to be at the origin of severe intergranular embrittlement of aluminum alloys. However, despite decades of research, no consistent picture of the physical mechanisms leading to the rapid formation of microscopic intergranular liquid layer has evolved so far. For instance, we still do not know whether Grain Boundary Penetration (GBP) involves the replacement of solid metal atoms by liquid metal atoms (through dissolution for instance) or if it proceeds by an invasion like process involving deformation and separation of the grains by an amplitude equal to the liquid layer thickness.

|

|

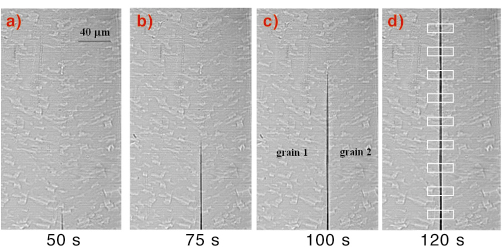

Fig. 151: Microradiographs showing liquid Ga penetration along an Al bicrystal grain boundary. The field of view is situated approximately in the centre of the 4 mm long grain boundary. The last image shows the regions of interest used to analyse the penetration rate. |

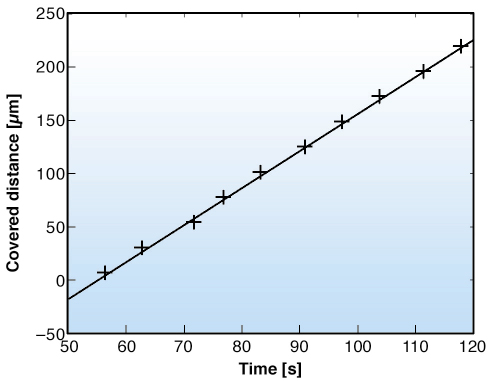

The use of the novel ESRF X-ray projection microscope, based on Kirkpatrick-Baez optics [1], has now provided an answer to this ongoing controversy: the unique combination of high resolution, bulk and in situ observation capabilities provided by this instrument has allowed us to simultaneously characterise the liquid film thickness (deduced from X-ray attenuation measurements) and any associated grain deformation (determined via image correlation techniques) during the penetration process. The experiments have been performed at a X-ray energy of 20.5 keV using pure Al bicrystal slices (10 x 4 0 x 0.8 mm3) which were imaged in close to edge-on configuration. In this acquisition geometry the detection limit for liquid Ga films can be as low as 5 nm [2]. Figure 151 shows four out of a series of several hundred projection images acquired during the penetration process of the bicrystal sample. The restricted field of view of about 150 x 250 µm was situated approximately in the middle of the 4 mm long grain boundary and the in situ observation was started with the initiation of penetration process at the lower extremity of the grain boundary and was continued until arrival of the penetration front at the other extremity of the bicrystal. The four images were chosen from the restricted time interval of about 70 seconds during which the penetration front has crossed the field of view. The analysis of the penetration kinetics from the images acquired in this time window reveals a linear penetration rate of 3.4 µm per second (Figure 152), in good agreement with previous measurements [2].

|

|

Fig. 152: Plot of the penetration distance versus time. |

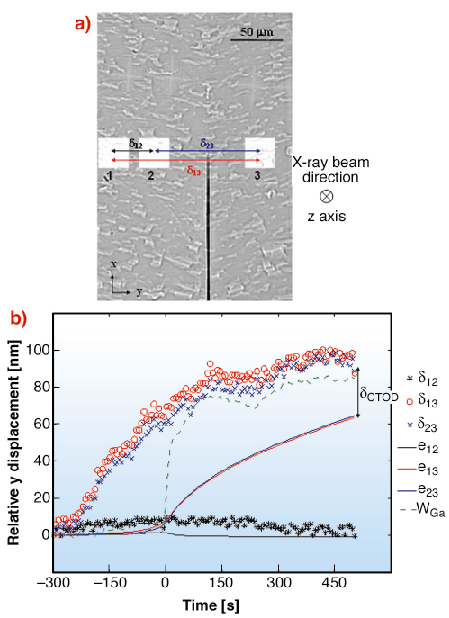

The simultaneous measurement of the grain deformation during the penetration process was based on image correlation of surface stains, left over from the chemical etching and subsequent polishing of the sample surface. Figure 153a depicts the three regions of interest, the relative displacements of which was analysed during the entire period of the penetration process. As can be seen from the plot in Figure 153b, the final amplitude of the relative displacements between the regions of interest situated on opposite sides of the grain boundary is close to the thickness of the liquid Ga film as estimated from the absorption measurements, whereas the relative displacement of the regions of interest situated on the same grain is close to zero. Note, however, that the onset of the relative grain displacement occurs about 200 s before the arrival of the Ga penetration front. This time lag can be explained in a consistent way, if one assumes that the penetration of the microscopic Ga layer can be assimilated to the propagation of a crack along the grain boundary. The experimentally observed displacement amplitudes as well as the time shift can be rationalised with fracture mechanics by assuming the existence of a very weak (0.045 MPa.m0,5) but constant stress intensity factor during the propagation of the liquid film. This rather surprising finding would suggest the existence of some kind of local crack driving force at the tip of the penetration front.

|

|

Fig. 153: (a) The three ROIs and their relative distances ( |

The answer to the initial question about the formation mechanism of the microscopic penetration layers, has given rise to a new question concerning the origin of the driving force: is it residual stresses in the bicrystal sample or some more fundamental physico-chemical mechanisms at the propagation front which maintain the crack propagation in the case of Al-Ga?

References

[1] O. Hignette, P. Cloetens, G. Rostaing, P. Bernard, C. Morawe, Rev. Sci. Instrum. 76, 063709 (2005).

[2] W. Ludwig, E. Pereiro-Lopez, D. Bellet, Acta Mater. 53, 151 (2005).

Principal Publication and Authors

E. Pereiro-Lopez (a,b), W. Ludwig (c), D. Bellet (a,b), P. Cloetens (b), C. Lemaignan (a,d), PRL 95, 215501 (2005).

(a) ENSPG, INPG, Saint Martin d’Hères (France)

(b) ESRF

(c) INSA de Lyon (France)

(d) CEA Grenoble (France)