Insertion Devices

The complete list of Insertion Device segments installed on all ESRF beamlines can be consulted at: http://www.esrf.fr/Accelerators/Groups/InsertionDevices/Engineering/Ids/Installed_IDs

The gradual replacement of 16 mm external aperture ID chambers with 10 mm aperture chambers is followed by an appropriate refurbishment of the undulator segments. As a result the long-standing 42 mm typical undulator period of a fully tuneable undulator has evolved into a 32-35 mm period.

|

|

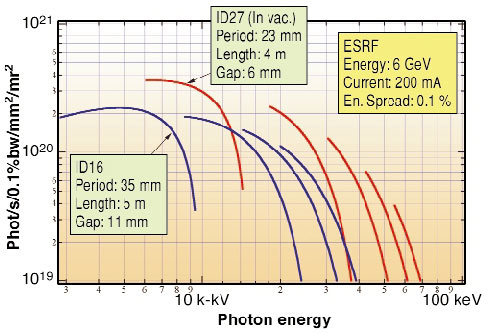

Fig. 178: Brilliance achieved on ID16 and expected brilliance for ID27 with two in-vacuum undulators operated at a minimum gap of 6 mm. |

In 2003, three in-vacuum undulators were manufactured. All three devices will be installed during the winter shutdown. They are dedicated to operation at high photon energy (40 keV-100keV) inaccessible with conventional undulators (see Figure 178). The status of ESRF in-vacuum undulators is summarised in Table 7.

|

|

Table 7: Status of in-vacuum undulators, all of them based on Sm2Co17 permanent magnet material. The stated maximum field integrals apply to both the vertical and horizontal field integrals to all gap values between 30 and 6 mm. PPM stands for the pure permanent magnet technology while hybrid structures are made of permanent magnets and iron poles. The phase errors are given at the minimum gap where the requirements are most severe. |

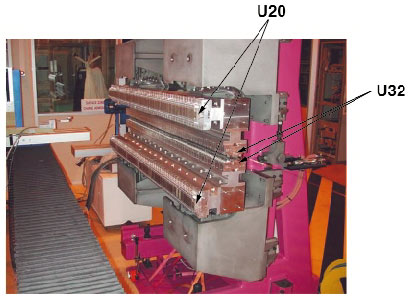

The last device in Table 5 (ID11 U22) is a hybrid undulator based on permanent magnets and soft iron poles. For the same period and gap, hybrid undulators provide higher peak fields than PPM devices. This is particularly relevant to in-vacuum undulators where the gap/period ratio reaches 0.3. Indeed, the measured peak field of the newly built ID11 U22 hybrid undulator is 0.875 T for a gap of 6 mm while it reaches only 0.72 T for a pure permanent magnet undulator of the same period and magnetic gap. Due to specific difficulties in the shimming, the hybrid technology has so far been avoided for in-vacuum undulators. Following a thorough study carried out in 2003 with the ID11 U22 hybrid undulator, it is now believed that most difficulties have been solved. For obvious reasons pertaining to performance, all future in-vacuum undulators will use the hybrid technology. In 2003 a prototype revolver support was built. Three additional support structures are expected for delivery at the end of 2003. The revolver support can accommodate two different magnetic assemblies mounted on a rotating girder (see Figure 179).

|

|

Fig. 179: Revolver support equipped with a U32 and a U20. This device is now installed on the ID18 straight section. |

Such a structure is designed to be interchangeable with any existing 1.6 m undulator segment in operation. A typical use of the revolver support involves a non-tuneable short period undulator (17 to 27 mm) providing 2-3 times enhanced brilliance in a limited photon energy range and a standard fully tuneable undulator (32 to 35 mm).

The status of revolver development is presented in Table 8.

|

|

Table 8: Status of revolver undulators, all devices are 1.6 m long and will be operated with an 11 mm minimum magnetic gap. |

In parallel to the intensive production of new insertion devices, mechanical wear on one of the oldest magnetic measuring benches was discovered, preventing the completion of phase shimming. A new Hall probe-scanning bench has been designed, built and put into operation in 2003. It makes use of the recently available linear motor which allows a scan to be made at a speed 4 times higher with higher mechanical stability and less vibration resulting in higher accuracy and improved repeatability (x5) of the measured field. A copy of such a bench has since been produced for the Swiss Light Source.