- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2003

- X-ray Imaging

- Investigation of the Porosity in Icosahedral Al-Pd-Mn Quasicrystals

Investigation of the Porosity in Icosahedral Al-Pd-Mn Quasicrystals

Defects are known to modify the physical properties of crystalline solids. This general feature also applies to quasicrystals, and it is therefore necessary to obtain as perfect as possible quasicrystalline single grains to identify intrinsic or defect-related properties. High quality quasicrystals have been grown that display rocking curve widths comparable to those of the best metallic crystals. Nevertheless, porosity is systematically observed in the volume of Al-Pd-Mn quasicrystals. These pores occupy a volume fraction much higher than the one observed in usual crystals (like Al), and their size can also be approximately 1000 times bigger in the quasicrystal than in the simple metal. The formation mechanisms of pores known from crystals do not seem to explain satisfactorily the porosity in quasicrystals and hence the origin of these pores remains unclear. Two hypotheses have been proposed to explain the occurrence of porosity. The first one assumes that pores are generated from the condensation and migration of thermal vacancies [1], whereas the second suggests that they could be an intrinsic characteristic of the quasicrystalline structure [2]. When starting the present work, there was no experimental evidence proving the overall validity of one of these hypotheses.

We have performed an in situ study, using synchrotron X-ray phase contrast radiography, of the porosity evolution in an icosahedral Al-Pd-Mn quasicrystalline single grain during two annealing cycles up to 800°C. The high-temperature experiments were carried out at the ID19 beamline in an unstrained sample heated in an ultra high vacuum chamber designed at the CRMC2 (Marseille, France). The phase contrast radiographs were recorded on a CCD-based camera, using an optics providing a spatial resolution of the order of 1-2 µm.

|

|

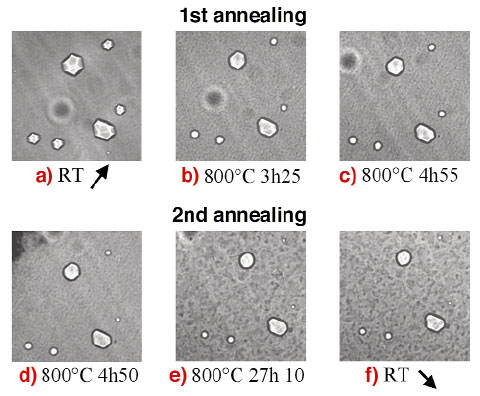

Fig. 133: Evolution produced by annealing at 800°C, of the porosity in an Al-Pd-Mn quasicrystalline single grain. |

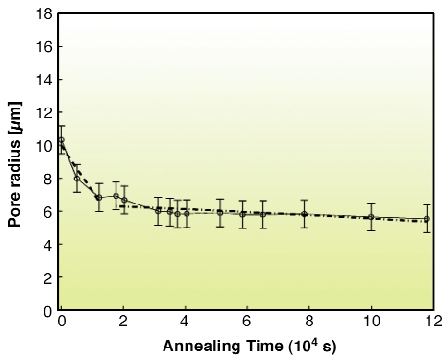

Figure 133 shows the porosity evolution in a small region of the sample during both annealing cycles. The size of pores decreases very rapidly during the first annealing cycle (Figures 133a to 133c). Moreover the shape of the pore images changes from faceted to round and the white line contrasts observed inside the pores images, which are associated with the edges of the dodecahedral shape of the pores, disappear. During the second annealing cycle (Figures 133c to 133e), the sizes of the pores further decrease, though less rapidly than in the first cycle. The shape of the pores images becomes more and more round with the annealing time. Two different parts can be observed in the shrinkage curves shown in Figure 134 (independently of the pore size and of the number of cycles): a steep first part, composed of few data points, with a high shrinkage rate (part I) and a second one with a smaller shrinkage rate (part II). These two shrinkage regimes were analysed using the diffusion-annealing model developed by Volin and Balluffi [3] for the shrinkage of nanometric pores in thin quenched and annealed foils of pure crystalline aluminium. This model assumes that atoms are transported to pores from the external surfaces by migration of vacancies and that a local vacancy equilibrium is maintained at all interfaces, implying that the kinetics is diffusion-controlled. The "part II" regime was found consistent with the self-diffusion of aluminium whereas the "part I" one was explained by an accelerated diffusion in the deformed structure or an equilibration of the vacancy concentration in the bulk.

|

|

Fig. 134: Shrinkage of the pore dimension with annealing time. |

These results indicate an influence of the vacancy diffusion on the high temperature evolution of porosity that could support the hypothesis of vacancy condensation. However, such a simple approach should lead to a uniform distribution of pores in the volume of quasicrystals. This is not consistent with the observed variation of the size distribution of pores, which could indicate more complex influences, during the solidification process, on the porosity formation. In order to check this hypothesis as well as to get an insight of the porosity nucleation mechanisms, in situ solidification experiments are currently in progress.

References

[1] C. Beeli, T Gödecke and R. Lück, Phil. Mag. Let. 78(5), (1998), 339.

[2] C. Janot, L. Loreto, R. Farinato, L. Mancini, J. Gastaldi and J. Baruchel, Mat. Res. Soc. Proc. 553, (1999), 55.

[3] T. E. Volin and R.W. Balluffi Phys. Stat. Solidi, 25, (1968), 163.

Principal Publication and Authors

S. Agliozzo (a), J. Gastaldi (b), H. Klein (c), J. Härtwig (d), J. Baruchel (d), E. Brunello (d), Phys. Rev. B, accepted.

(a) Institute for Scientific Interchange, Torino (Italy)

(b) CRMC2, CNRS, Marseille (France)

(c) CNRS, Grenoble (France)

(d) ESRF, Grenoble (France)