- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2002

- X-ray Imaging

- Visualisation of Grain Boundary Migration

Visualisation of Grain Boundary Migration

Traditional methods for quantitative measurement of grain boundary (GB) migration consist of consecutive post-mortem observations of a migrated branch of the boundary on the surface of a bicrystal by light microscopy [1]. Recent progress in the study of this problem is represented by an application of synchrotron radiation (SR) offering many advantages for in situ observation [2].

For our study of GB migration by in situ synchrotron radiation diffraction topography, a specimen 4 mm wide and 1 mm thick was prepared of a bicrystal with the {130} GB [3]. The boundary was perpendicular to the largest specimen surface (001) and made an angle of 45° with both side surfaces. The measurements at 965C were done at beamline ID19, using a special high-temperature vacuum stage. At this temperature, the boundary migrates towards the centre of its curvature to reduce its energy (= area). Transmission topographs were taken using monochromatic beam ( = 0.0207 nm, 420 symmetrical reflection for both grains,

= 0.0207 nm, 420 symmetrical reflection for both grains,  = 9.44). The diffracted beam was recorded by a FReLoN camera [4]. As the bicrystal contained sub-grains misoriented up to tens of minutes, the sample was rocking over this angle while the topograph was recorded. The recording time, approximately 1 minute, was comparable to the exposure time for photographic plates, but the records could be taken in shorter intervals without interrupting the experiment. This fact is very important when fast changes have to be registered.

= 9.44). The diffracted beam was recorded by a FReLoN camera [4]. As the bicrystal contained sub-grains misoriented up to tens of minutes, the sample was rocking over this angle while the topograph was recorded. The recording time, approximately 1 minute, was comparable to the exposure time for photographic plates, but the records could be taken in shorter intervals without interrupting the experiment. This fact is very important when fast changes have to be registered.

|

|

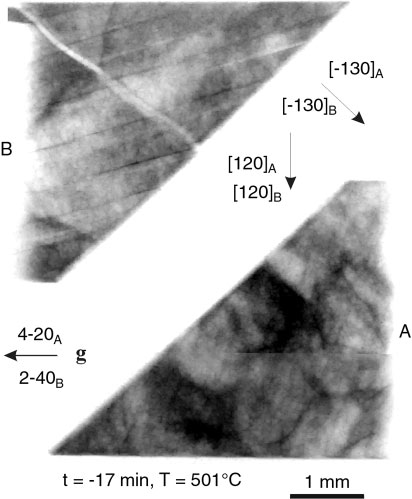

Fig. 94: SR topograph characterising planar boundary before start of grain boundary migration. Fine details in the structure are magnetic domains and a sub-boundary in grain B, g is the diffraction vector. |

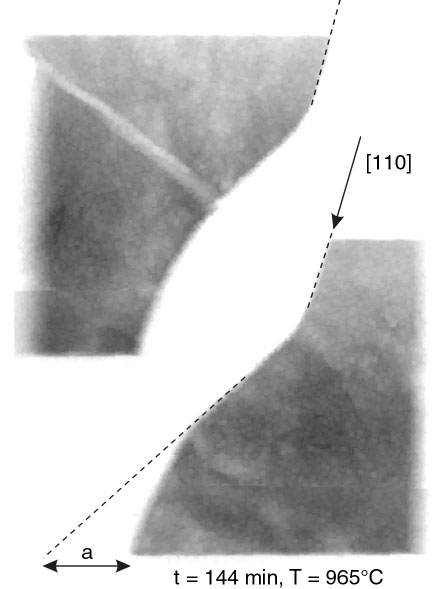

It is apparent from characteristic topographs that both branches of the originally planar GB (Figure 94) curve and migrate towards the centre of their curvature (Figure 95). The time dependence of the migrating distance, a = Ct1/2, on the side surface for each branch of the boundary provides the parameter C important for quantification of temperature and orientation dependent GB migration [1].

|

|

Fig. 95: SR topograph showing migrating boundary after 144 min. at 965°C. a is the migrated distance of the GB. The ( |

The in situ observation showed that the GB is circular with a right angle to the side surface at the beginning of migration. Later it tends to become straight with an angle of ~70° to the side surface and so, parallel to the [110] direction of the grain A of the bicrystal (Figure 95). The boundary is not exactly perpendicular to the largest sample surface but nearly parallel to the ( 10) plane as can be deduced from the width of its image on the transmission topographs and from post-mortem observation. Finally, good agreement was found between the data measured by SR topography and by light microscopy technique [1].

10) plane as can be deduced from the width of its image on the transmission topographs and from post-mortem observation. Finally, good agreement was found between the data measured by SR topography and by light microscopy technique [1].

The described results were achieved thanks to the high energy and intensity of synchrotron radiation, and the high sensitivity and good resolution of the FReLoN camera. The method is capable of providing the data necessary for the determination of basic characteristics of dynamical processes. Much more data can be collected in this way than using repeated annealing experiments. In addition, the in situ measurements may reveal many details elucidating the mechanism of GB migration and interaction of moving interface with lattice defects.

References

[1] P. Lejcek, V. Paidar, J. Adámek and S. Kadecková, Interface Sci. 1, 187 (1993).

[2] S. Tsurekawa, T. Ueda, K. Ichikawa, H. Nakashima, Y. Yoshitomi and H. Yoshinaga, Mater. Sci. Forum 204206, 221 (1996).

[3] S. Kadecková, P. Toula and J. Adámek, J. Crystal Growth 83, 410 (1987).

[4] M. Polcarová, J. Brádler, J. Gemperlová, A. Jacques and A. George, J. Phys. D: Appl. Phys. 32, A109 (1999).

Principal Publication and Authors

M. Polcarová (a), J. Brádler (a), A. Jacques (b), P. Lejcek (a), A. George (b), O. Ferry (b), J. Phys. D: Appl. Phys., accepted.

(a) Institute of Physics, AS CR, Praha (Czech Republic)

(b) LPM, Ecole des Mines, Nancy (France)