- Home

- Users & Science

- Scientific Documentation

- ESRF Highlights

- ESRF Highlights 2001

- Applied and Industrial Research

- Industrial Microtomography Applications at ID19

Industrial Microtomography Applications at ID19

X-ray imaging techniques, and in particular X-ray computed microtomography (CMT) [1], provides a valuable tool for applied research. These techniques are non-destructive and give access to three-dimensional (3D) images of various materials at the micrometer scale.

Over the past three years, an increasing number of industrial companies have used CMT, on the ID19 beamline, to solve problems they encounter. This is performed either by paying for beam time and expertise, or through collaboration with universities or research groups and peer-reviewed proposals. One of the keys to this success is that, in addition to confidentiality and rapid access, the ESRF now proposes a complete service, which includes the preparation of the experiment (discussion about the experimental feasibility, mechanical and electronic device preparation, when required), the experiment itself and data analysis (volume reconstruction in CMT, image processing, etc.).

Three selected industrial applications are presented, with the agreement of the industrial companies concerned. The first two originate from the cosmetics industry, which is one of the sectors of activity that benefit highly from microtomography, and the third from the chemical industry, more specifically for polyurethane foam processing.

Imaging of Soaps

Different kinds of soaps at different manufacturing stages were investigated. Figure 149 shows particle distribution in volume (3D rendering), with a voxel size of 1 micrometre. The aim of such an experiment was to identify the various soap components using quantitative information such as the linear attenuation coefficient, and to determine their shape, number and size.

|

Fig. 149: 3D rendering of soap - 512*512*256 voxels (voxel size: 0.95 µm3). |

Density Mapping of Hair

Using the holotomography technique [1], a study on hair was performed at very high resolution (pixel size: 0.33 µm). Figure 150 shows the result of 3D density mapping of human hair. This figure represents a 3D rendering of the hair, which shows the medulla as a lower density area within the cortex [2].

|

Fig. 150: 3D rendering of human hair (voxel size: 0.33 µm3). |

Polyurethane Foam Processing

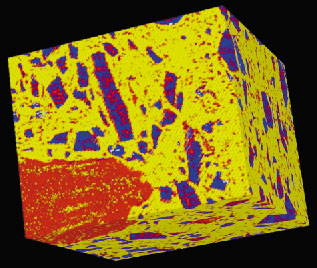

The large pixel size range (from 40 to 0.3 micrometres) available at ID19 allows complete studies in the domain of foam processing. The characterisation of foam closed-cell details on a large scale, with good statistics is possible. This implies the consecutive use of optics with a large field of view at low resolution and a small field of view at very high resolution in the same foam. Figure 151 shows two reconstructed slices of the same foam, using low and high resolutions, respectively.

|

Fig. 151: Reconstructed slices of the same closed-cell foam at low (pixel size: 30 µm) and high (pixel size: 0.95 µm) resolutions. |

It is clear that microtomography is well adapted to the resolution of many types of industrial problems, and it is expected that the number of industrial experiments and the range of topics will extend over the next few years. The new experimental hutch of the ID19 beamline, together with instruments entirely devoted to microtomography, will allow a fast and easy access, as well as better management of the beam time for industrial experiments.

References

[1] X-ray Tomography in Material science, Eds. J. Baruchel, J.-Y. Buffière, E. Maire, P. Merle and G. Peix, Hermès Edition (2000).

[2] P. Cloetens, E. Boller, W. Ludwig, J. Baruchel and M. Schlenker, Europhysics News, March/April, 46-50 (2001).

Author

E. Boller

ESRF