Insertion Devices

We have 3 insertion devices on ID19:

- 2 undulators: U32 and U44

- 1 wiggler

How to use our undulators (U32 and U44)

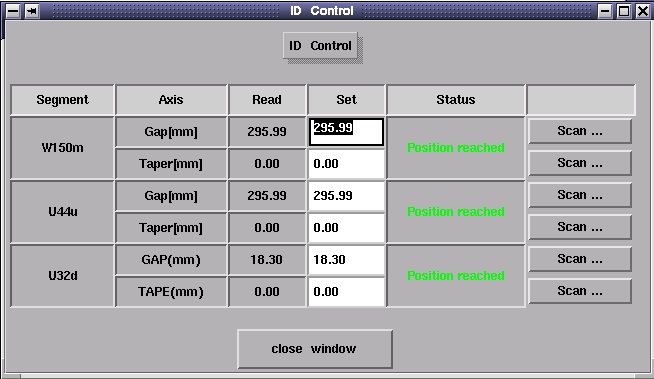

1) open gaps of both undulators: ~295.99 mm

- in Insertion Device Control application (on small monitor near the printer) fill corresponding "set" columns and then press "enter"

2) set diamond window for undulators

(ring of 5 mm diameter mounted on the first attenuator axis: max. beam size = 25 mm)

- in SPEC application NATT: attshow (semi graphic showing all absorber axes and their state)

- 104 (set fourth absorber/window of the first axis into the beam, which corresponds to the small diamond for undulators)

3) close wiggler gap to ~ 50 mm (always in ID Control application)

4) choose desired photon energy E and send monochromator to it

- for a "convenient" energy consult the tables with energies of various harmonics as a function of the gap of two undulators, note which undulator at which gap you desired

- in SPEC application VMONO: moveE E

5) check monochromatic beam with

- fluorescent screen in blue/white box: in SPEC application HMONO: mv scr 0

- Laue camera: need to be put manually in the position in the experimental hutch where beam is expected (for example on hdiffr)

6) CHECK THAT DIAMOND WINDOW FOR UNDULATORS IS REALLY SET

- open primary slits horizontal gap pshg more than 5 mm up to you can see on fluorescent screen or Laue camera the round borders of the diamond window

- in SPEC application SSLITS: mv pshg 7 or in the graphical primary slits application set pshg to 7 and enter

- if it is not the case, don’t close the gap of any undulator and consult a specialist (local contact)

7) from now check periodically the quality of the vacuum and the eventual heating of various optical elements (mainly primary slits and monochromator) This is particularly important when using U44.

-

- vacuum values should not exceed 10-8 mbar, you find them in graphical general beam line application called Vacuum

- temperatures should not exceed 50°C, they are in graphical application called Signal Monitoring

-

in the case of worrying values:

-

a) try to use the smaller beam possible (close primary slits)

b) change from U44 to U32

c) close Front-End and consult a specialist (as local contact)

-

a) try to use the smaller beam possible (close primary slits)

8) open wiggler gap to ~ 295.99 mm (always in ID control application)

9) close ONE undulator gap to desired value, chosen in item 4 (always in ID control application)

10) perform energy scan (be sure that monitor is operational)

-

-

in SPEC application VMONO (example if E=10.5 keV desired):

nrj_scan 10 11 10 1- nrj_scan minE maxE_of_scan_interval number_of_steps counting_time_per_point

-

in SPEC application VMONO (example if E=10.5 keV desired):

11) send monochromator to the energy corresponding to the maximum of the curve obtained by energy scan ( maximum_E)

-

- in SPEC application VMONO: moveE maximum_E

12) take away fluorescent screen if in the beam

- in SPEC application HMONO: mv scr -90

13) you are ready to work !